Equipment/Dewalt Table saw

Usage

- Do not use this without training.

- If you need to remove the safety guard, replace after use. Do not lose the butterfly nut.

- If you need to remove the riving knife (for instance, to use a sledge), you should not need to dismantle the device, Unplug, remove throat plate, push the sprung-loaded bolt on the riving knife bracket to release. Replace after use.

- If you need to remove the mitre gauge, put it back in the groove afterwards. Do not over-tighten the thumb nut.

- Do not attempt to move the rip fence or saw angle without loosening the locking levers (This breaks the rail gearing, and is stupid).

- Lock all locking levers before cutting.

- Do not remove the laminated instructions from the vicinity of the table saw. Knowledge is power. Knowledge of power tools prevents maiming and death.

- Always leave the saw with all safety features in place. The next user could be a novice.

Mailing list conversations on it:

- [1]

- [2]

- [3]

- [4]

- Safety discussion. Note link to YouTube video about kickback, riving knifes, safety guards

- Youtube video about table saw safety, essential viewing

- Donated to hackspace.

Maintenance / New parts

The saw gets a lot of use so the blade wears out, if the saw is burning through your cut the blade most likely needs replacing Additionally the riving knife keeps disappearing, this is an important safety feature and should be present at all times.

If the blade needs replacing or riving knife gets lost again you can help! Just buy the new parts online, fit them and claim the costs back on the Hackspace Expenses. If you are not comfortable doing this please report to the mailing list and somebody else should be able to help. A sharp blade and riving knife make the saw massively safer to use, please do not ignore these issues, at the very least report them

- Tested as working in new Hackspace 25 August 2018. Couldn't locate mitre fence.

- Cleaned out machine - the interior was caked in sawdust causing a fire risk, and located all parts ready for Hackspace move. 24 Feb 2018. (Simon H)

- Cleaned out machine since build up of sawdust and cutting detritus was blocking the angle adjustment. Also reset fence alignment. 25 June 2017 (Simon H)

- New blade and riving knife added June 2017 (Matt H).

- New blade and riving knife added January 2017 (Simon H).

- Mitre fence went missing in the move. (Simon H)

- Riving knife has a habit of jumping out of the bracket (clamp doesn't hold it securely)

- New mitre fence fitted 10 October 2018 (Simon H)

- Stripped down and cleaned out copious amount of caked in damp sawdust was preventing safe blade height adjustment, adjusted riving knife bracket to stop it wobbling 10 Jan 2020 (Simon H)

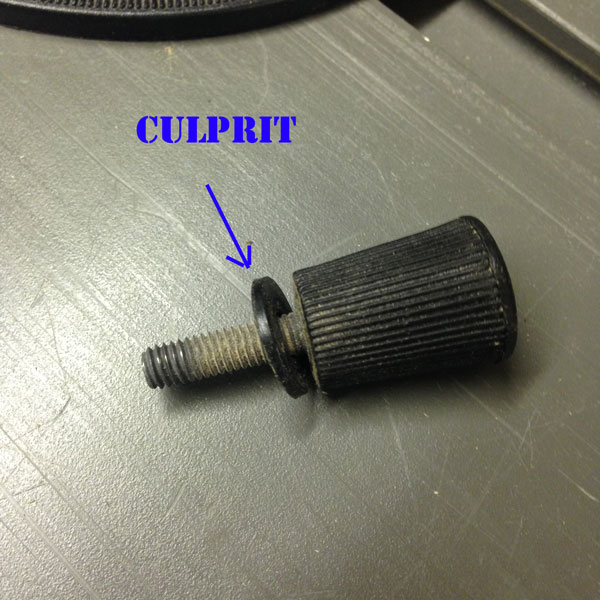

How a misplaced washer increases the risk of somebody cutting their fingers off (or worse!)

I noticed the mitre gauge is not moving smoothly across the top surface at all. This forces the user to use excessive force when pushing a piece of wood at an angle towards the blade. This can be very dangerous and increases the risk of somebody accidentally getting his hand hit the blade. I definitely would not want to be using this machine like that! It also prevents you from making a clean, smooth cut through the wood. So, after trying to figure out why the mitre gauge gets stuck halfway the table top when sliding it I came to the conclusion that the little plastic washer underneath the tightener knob doesn't belong there. I've moved it from underneath the knob to underneath the gauge (please see pictures). That seems to have solved the problem. Mitre gauge now running smoothly across the full length of the guide rail. I suggest we keep the washer where it is now. Maybe it saved somebody's hand or fingers already, who knows.

Thanks to this table saw guide to help me pinpoint the problem.

Manual available at

http://service.dewalt.co.uk/Products/ProductDetail.aspx?ProductID=9347&BOMRegionID=1

Parts Diagrams