Difference between revisions of "Project:25-hpamakers-reprap"

Samthetechie (talk | contribs) |

|||

| Line 25: | Line 25: | ||

===3D Printer=== | ===3D Printer=== | ||

| − | [ | + | [Prusa Mendel http://reprap.org/wiki/Prusa] |

== Mendel Specifications == | == Mendel Specifications == | ||

Revision as of 15:01, 11 May 2011

Other similar projects icrobotics.co.uk

<rss>http://samthetechie.blogspot.com/feeds/posts/default/-/25</rss>

Aim

Get a working 3d printer. Make shit. Be awesome.

Who?

What?

Delicious Links

<rss>http://feeds.delicious.com/v2/rss/samthetechie/25</rss>

3D Printer

[Prusa Mendel http://reprap.org/wiki/Prusa]

Mendel Specifications

The table below outlines the specifications of the machine.

| Metric | |

|---|---|

| Model | Reprap II: Mendel "Mendel" |

| Technology | FFF (Fused Filament Fabrication)/Thermoplastic extrusion |

| Price of all materials | €350 |

| Annual Service Cost | Occasional oiling = €5. It can print its own replacement printed parts at material cost. |

| Size | 500 mm (W) x 400 mm (D) x 360 mm (H) |

| Weight | 7.0 kg. |

| Build Envelope | 200 mm (W) x 200 mm (D) x 140 mm (H). |

| Materials | PLA, HDPE, ABS & more. Uses ø 3 mm filament. |

| Material Cost | PLA: €22/kg, HDPE: €11/kg, ABS: €17/kg. |

| Speed | 15.0 cm3 per hour solid (test done for PLA, similar for others). |

| Accuracy | Diameter of nozzle 0.5 mm, 2 mm min. feature size, 0.1 mm positioning accuracy, layer thickness 0.3 mm |

| Finish | Fair |

| Volume of printed parts to replicate | 1110 cm3 |

(With the standard infill settings the 15.0 cm3 per hour solid extrusion rate is equivalent to a built volume rate of 19.0 cm3 per hour.)

Consumables

Blue Decorator's Tape

PLA, HDPE, ABS Filament

Computing

Netbook with Solidworks and Reprap Host Software.

Power

Converted 300W ATX Power Supply. +12V and GND. 5A current.

Electronics

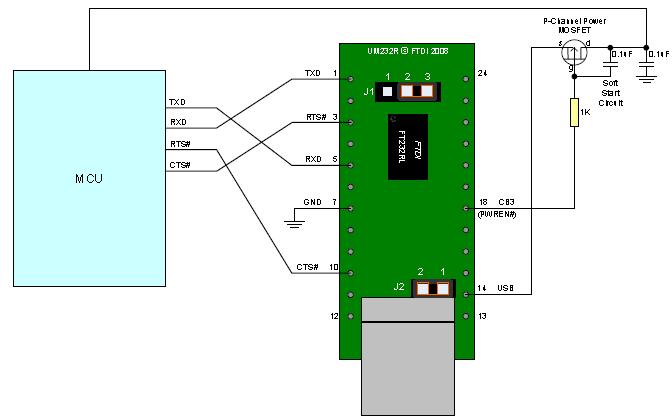

USB to TTL Adapter

Based on the FTDI FT232R.

Currently the connector is wired such:

GND DCD# VCC TXD RXD RTS#

While the Sanguino (at least v1.0) expects:

GND GND [USB_5V (VCC)] RXD TXD RTS#

From the datasheet:

It can be inferred that the correct terminals on the cable in Fig. 1 should be:

GND GND VCC TXD RXD CTS#

All said, the extruder and main motherboard (gen 3 reprap electronics) have been successfully flashed using this controller so perhaps the critical lines are in, one GND, VCC and TXD plus RXD which afaik handle the data transmission.

Motherboard

Stepper Motor Driver

Where?

Why?

How?

Development Milestones

Ordering

Obtain all the parts to make our Mendel

Check Parts List (27/6/10). Order Leftover Parts (complete 28/6/10).

Construction

Begin Construction: Build Manual Downloading and Installing RepRap on your computer

Latest build from sourceforge.

Circuit board construction

2.1 Soldering Opto Endstops x 3 (completed 1/7/10). 2.2 Soldering USB to Serial. 2.3 Makerbot Stock PCB for usage as Mendel Modification. 2.4 Modify ATX power supply with XLR connector (completed 1/7/10).

Microcontroller firmware installation

Mechanical construction

Electronic wiring

Testing

Check Electronic Wiring Check Firmware Check Mechanical Construction

Stepper Motor Drivers + Mainboard

5 Finish Testing

Commissioning

Begin printing Make first model Make first part Make first set of parts

Google Docs

Printed parts

We now have the beginnings of a sorting system, to make it easy to keep track of what has been printed.

Roadmap:

- 1. Add labels to front of trays, identifying components and quantities present in each tray.

- 2. Add printouts (paper media) to the wall, showing parts, quantity required and assemblies.

- 3. Add additional shelving to hold (bigger) assemblies.

Where?

London Hackspace: http://london.hackspace.org.uk/

Why?

Because we want a 3D printer!