Project:Nanode/Building a Nanode: Difference between revisions

(→Step 2) |

(→Step 2) |

||

| Line 51: | Line 51: | ||

'''Useful Tips''' These arose from the experiences of 30 new builders over the London Hackspace Nanode Weekend | '''Useful Tips''' These arose from the experiences of 30 new builders over the London Hackspace Nanode Weekend | ||

1. Some kits will have been supplied with five of the 14 pin IC sockets. | 1. Some kits will have been supplied with five of the 14 pin IC sockets - see photo above. Just put two together to make up the 28 pin sockets, making sure you have the pin 1 notch at the correct end and not both ends! | ||

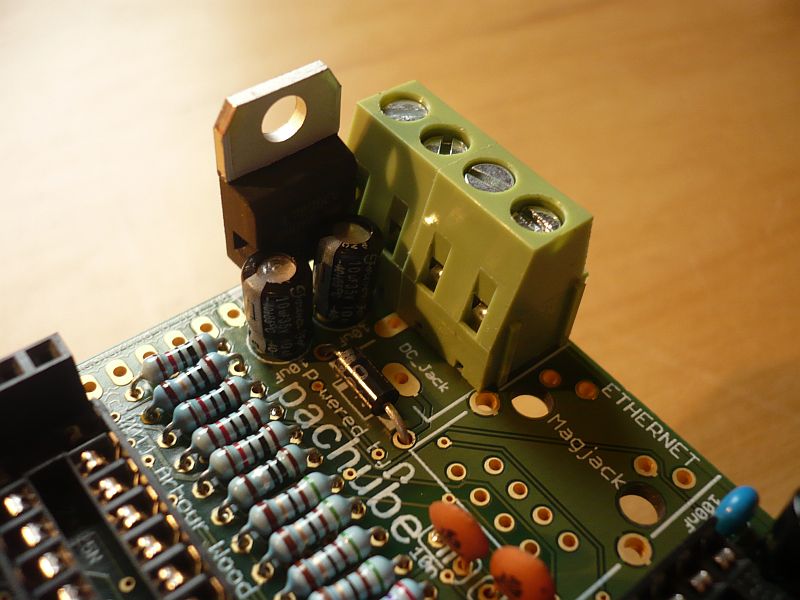

2. Assemble the two green screw terminal connectors into a single 4 way block, before you solder - you won't be able to do this if you solder them on individually! | 2. Assemble the two green screw terminal connectors into a single 4 way block as shown in the photo above, before you solder - you won't be able to do this if you solder them on individually! | ||

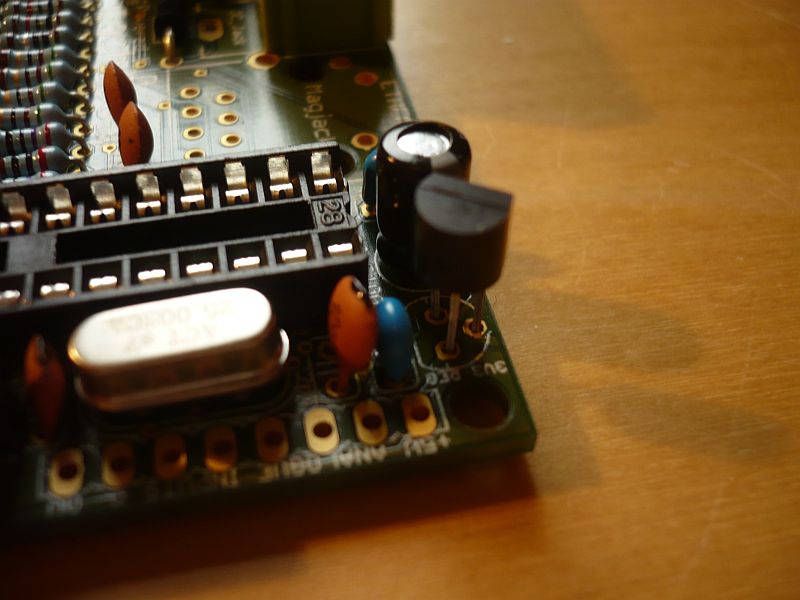

3. Space the two metal crystal cans about 1mm above the pcb. This prevents the risk of the metal can shorting to any of the vias underneath. | 3. Space the two metal crystal cans about 1mm above the pcb. This prevents the risk of the metal can shorting to any of the vias underneath. | ||

Revision as of 10:32, 11 June 2011

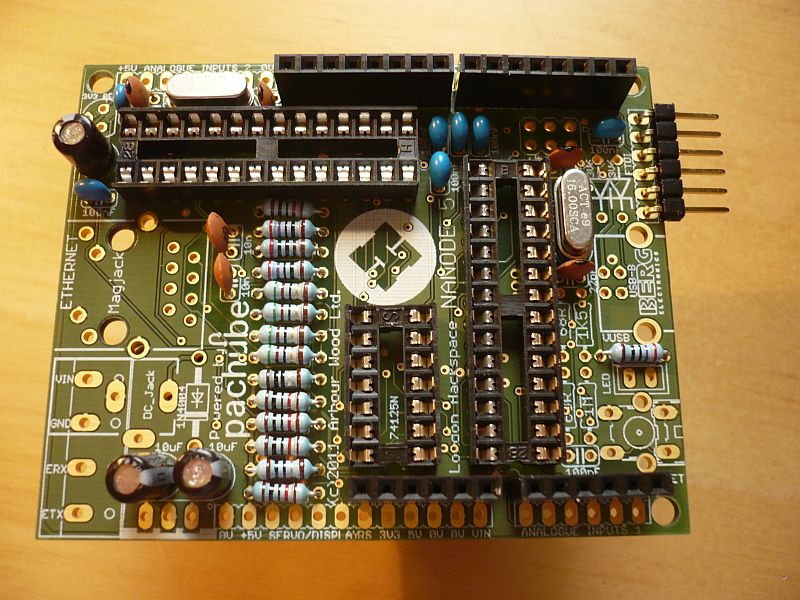

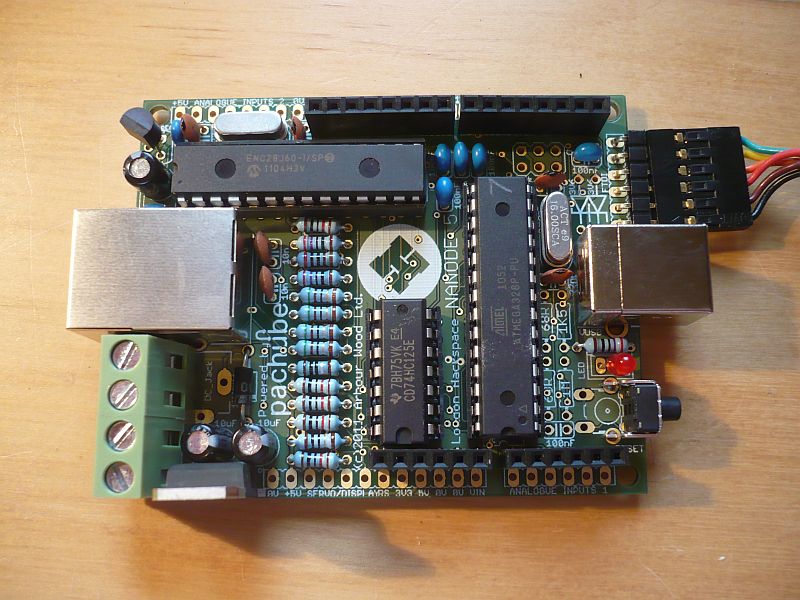

Building a Nanode - in Words and Pictures

Here's how to build up a Nanode as a step by step guide. It should take you a couple of hours.

Then you can move on to testing and Nanode Applications

Step 1

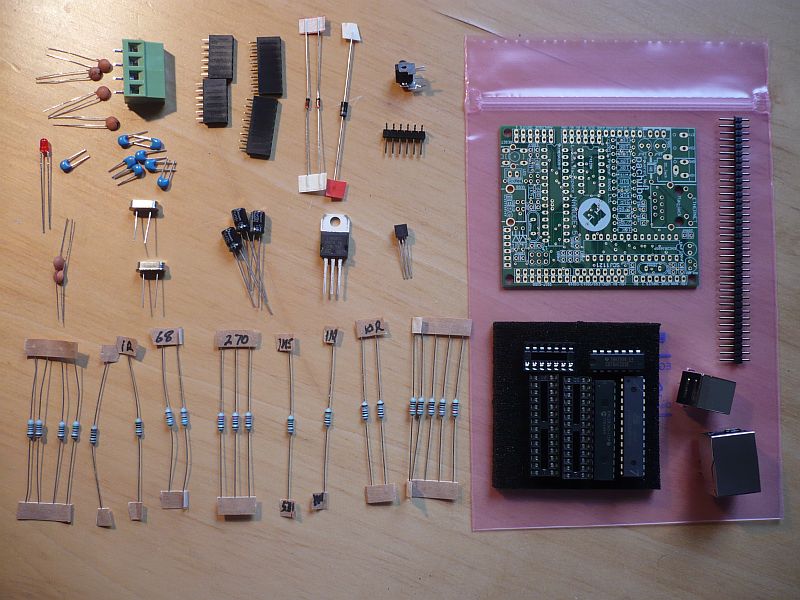

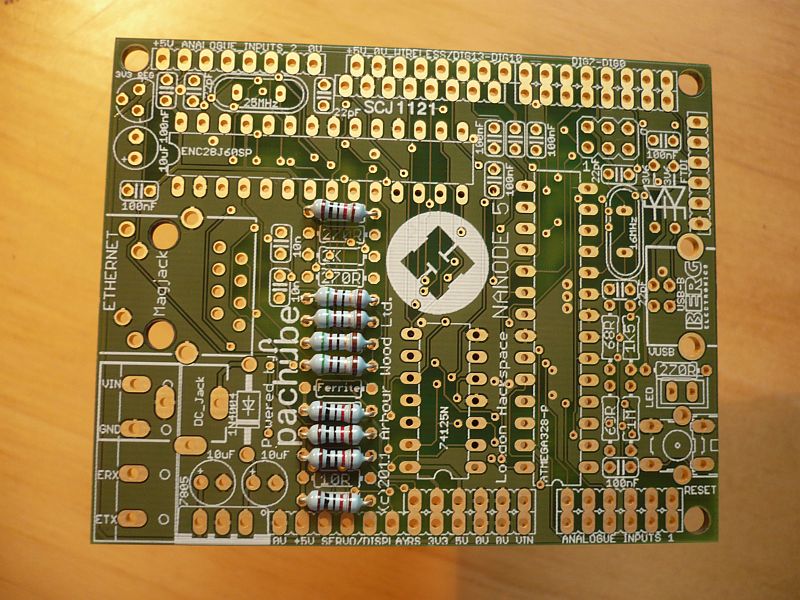

First identify the kit contents

Here you see all the resistors, capacitors, connectors, crystals and ICs needed to make the standard build of Nanode 5.

Everything should be supplied in a pink antistatic plastic "zip" bag. This early photo shows two 10R resistors - whereas there is only one needed.

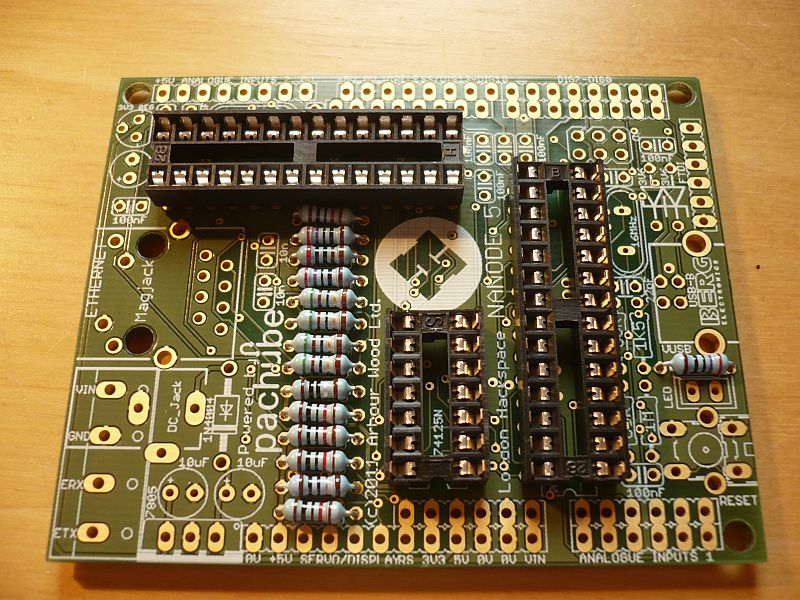

IC Sockets - special note

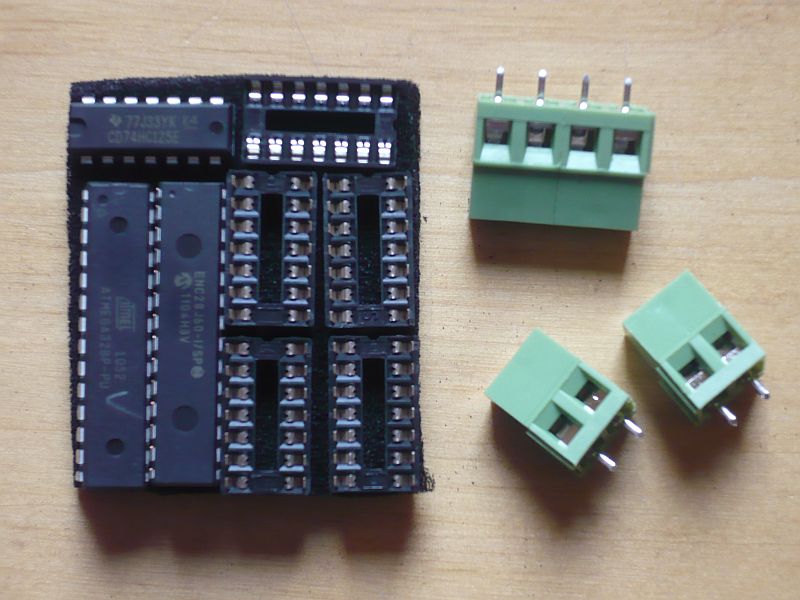

Some kits will have been supplied with five of the 14 pin IC sockets. This is because the supplier ran out of 28 pin sockets. No problem - Just put two together to make up the 28 pin sockets, making sure you have the pin 1 notch at the correct end and not both ends!

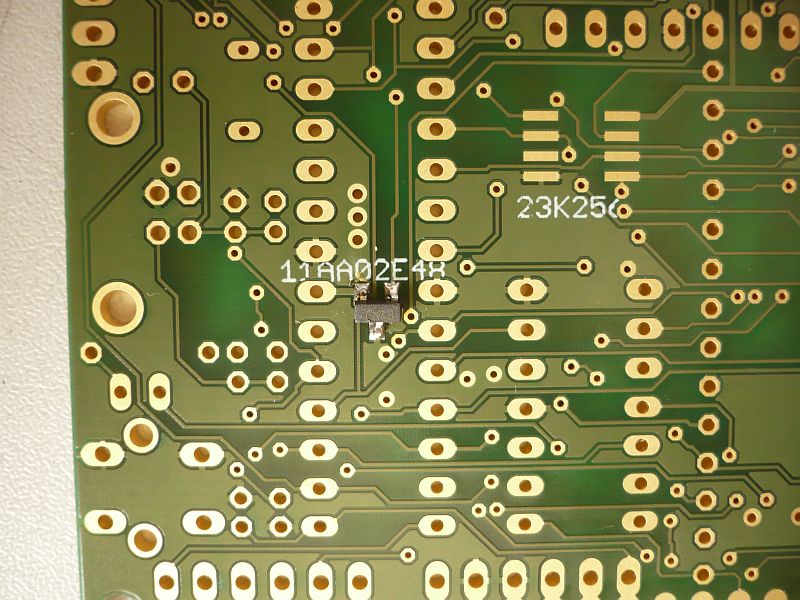

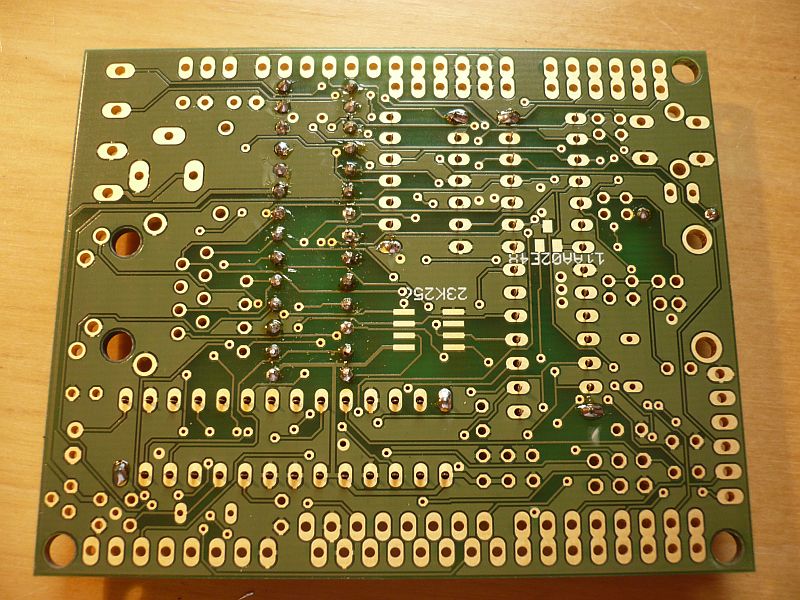

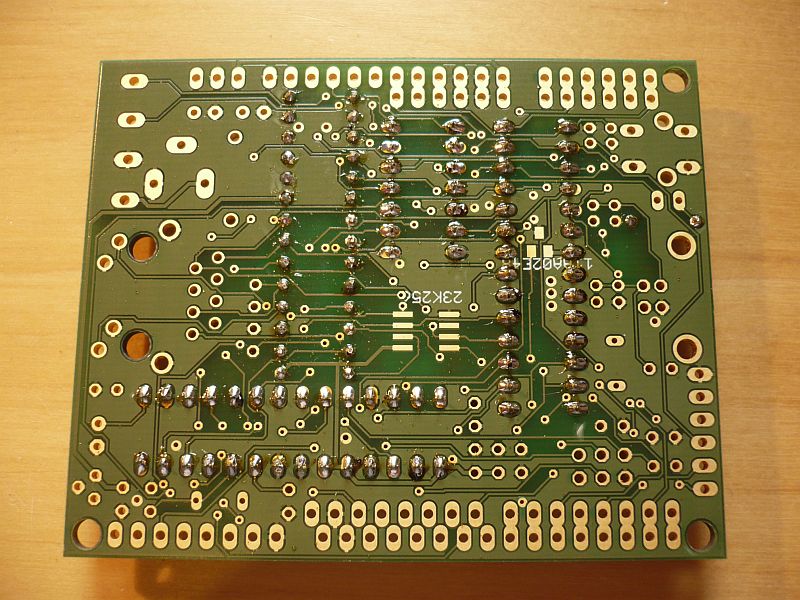

MAC Chip

If you have one of the later kits, you should find that the tiny MAC address IC has already been soldered in place on the back of the PCB.

This is the safest place to put it - as it would be very easily lost of put separately in with the rest of the kit components.

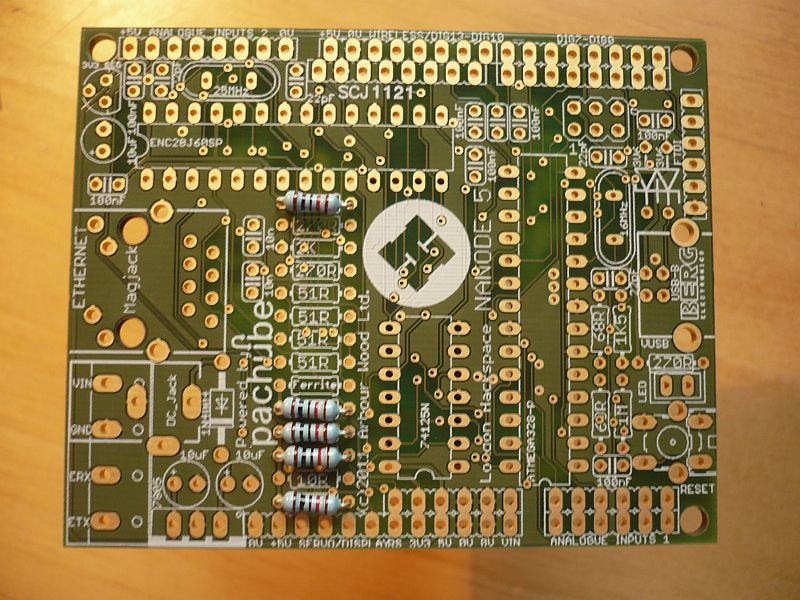

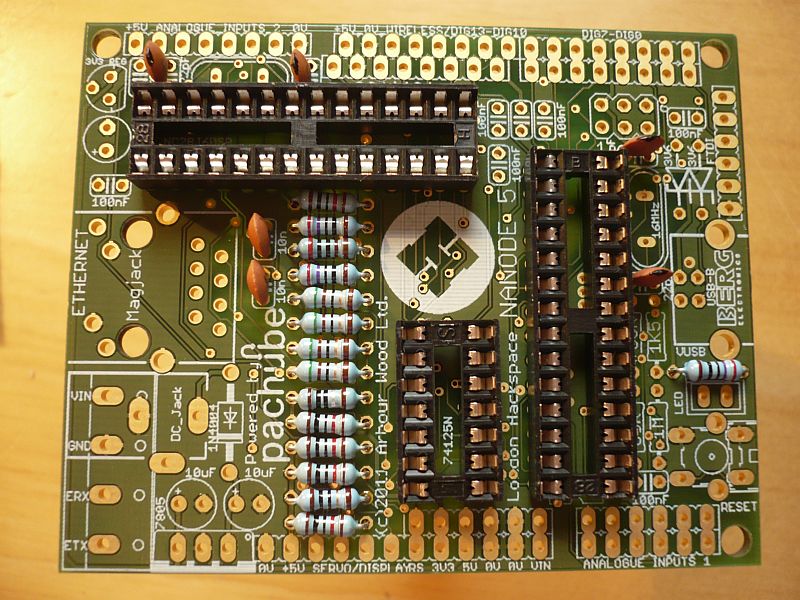

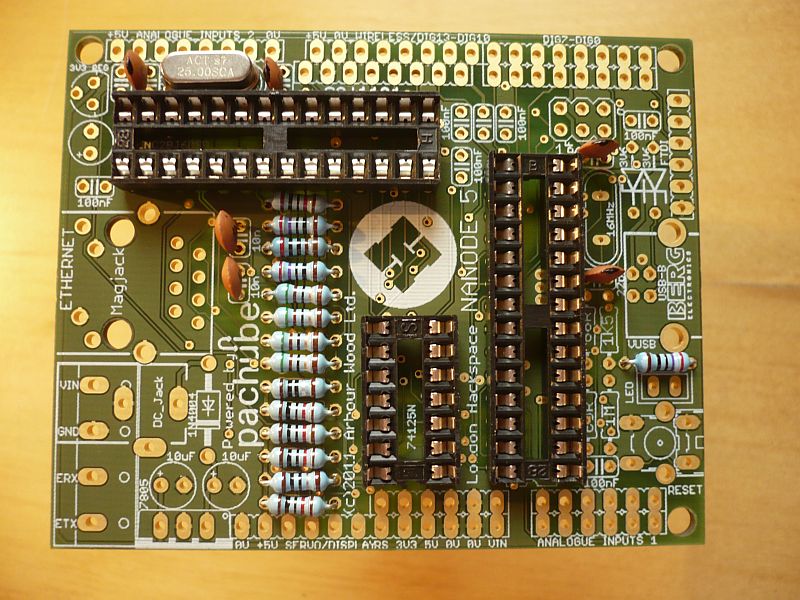

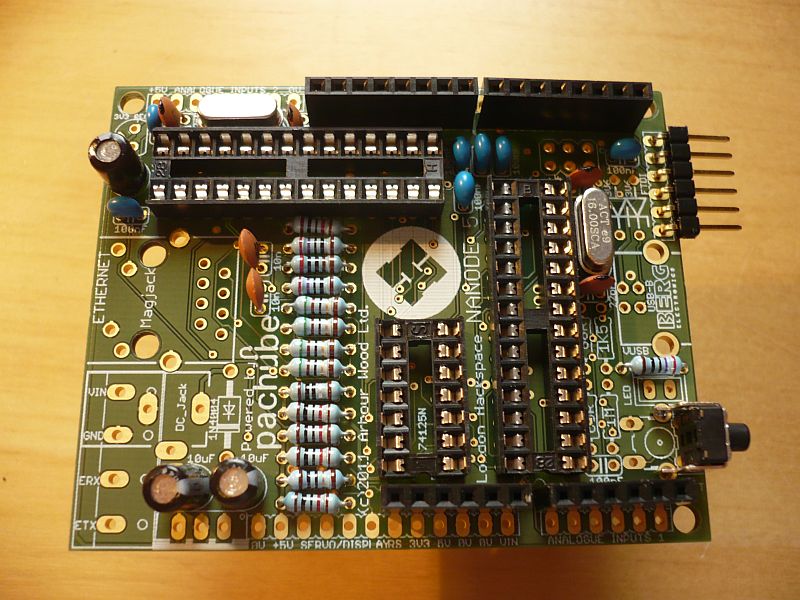

Step 2

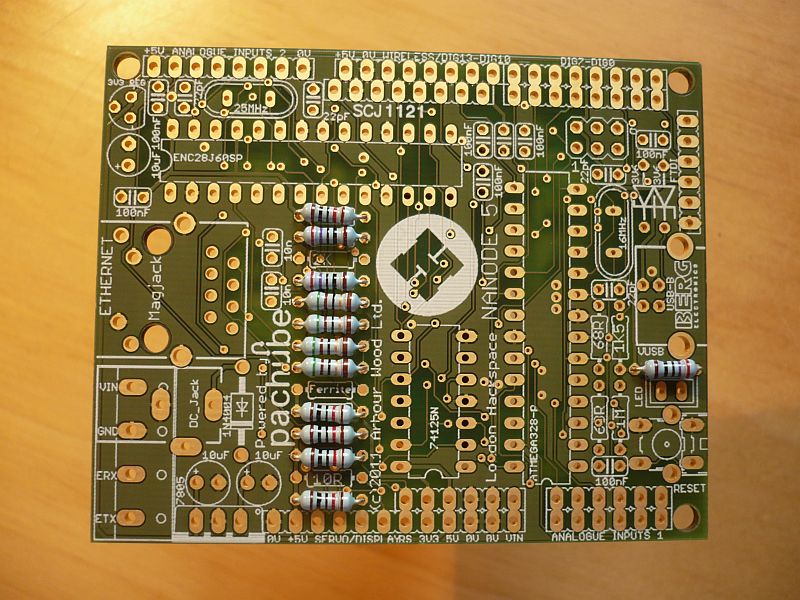

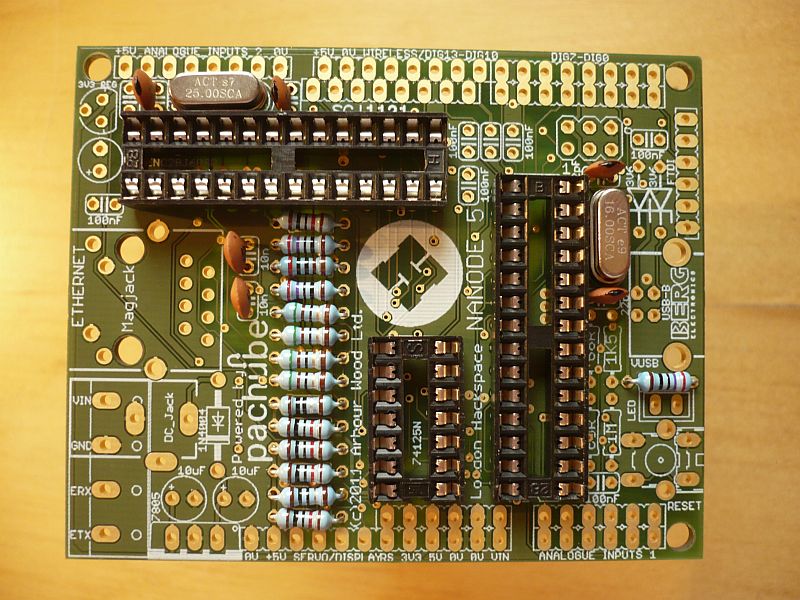

Now orientate the board so that the writing is positioned like this. Note how the component value has been written underneath or close by the component location.

This is the basic starting point for the build sequence. The pcb is built in an orderly sequence starting with the resistors and small components that are low on the board and then working up to the bulkier parts like connectors.

Building a Nanode is just a case of replicating the steps shown in the following picture sequence - no real electronics experience needed - just basic soldering skills.

Before you start

Read through this build sequence familiarising yourself with the proposed order of steps.

Useful Tips These arose from the experiences of 30 new builders over the London Hackspace Nanode Weekend

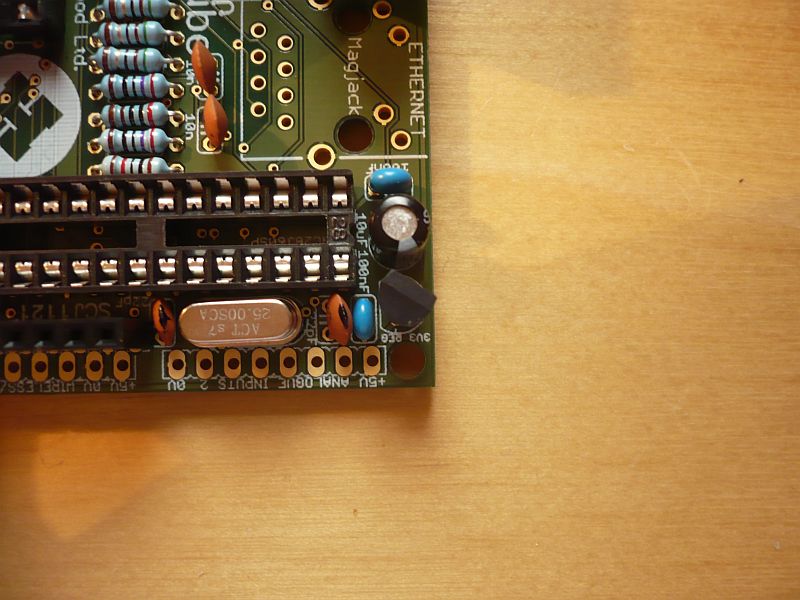

1. Some kits will have been supplied with five of the 14 pin IC sockets - see photo above. Just put two together to make up the 28 pin sockets, making sure you have the pin 1 notch at the correct end and not both ends!

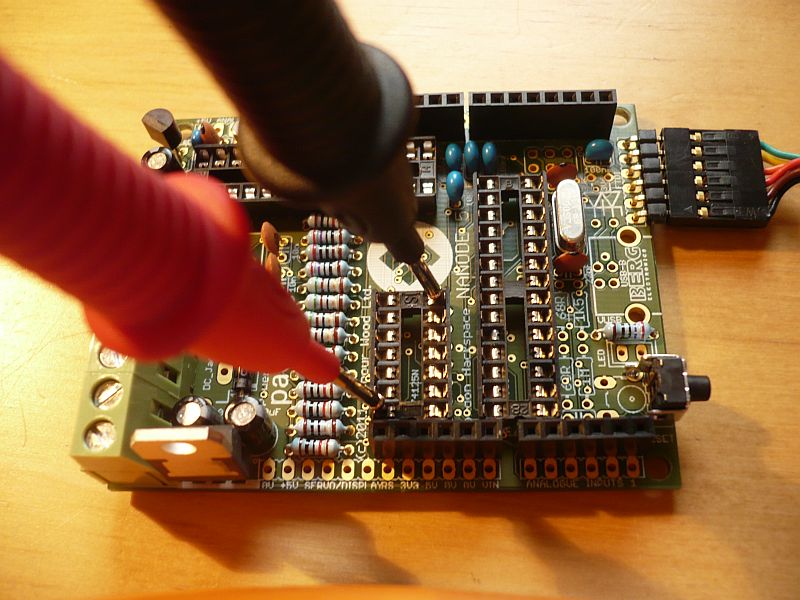

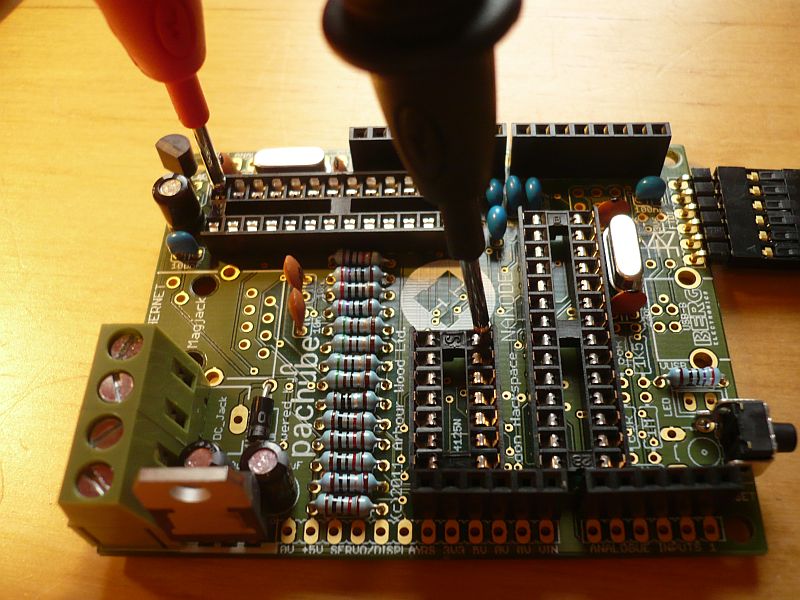

2. Assemble the two green screw terminal connectors into a single 4 way block as shown in the photo above, before you solder - you won't be able to do this if you solder them on individually!

3. Space the two metal crystal cans about 1mm above the pcb. This prevents the risk of the metal can shorting to any of the vias underneath.

4. Pay particular attention to the orientation of the 3V3 regulator - note it's NOT the same as the screen print legend. We had to change the regulator for one capable of more current and it came with a different pin-out. Follow the photographs carefully.

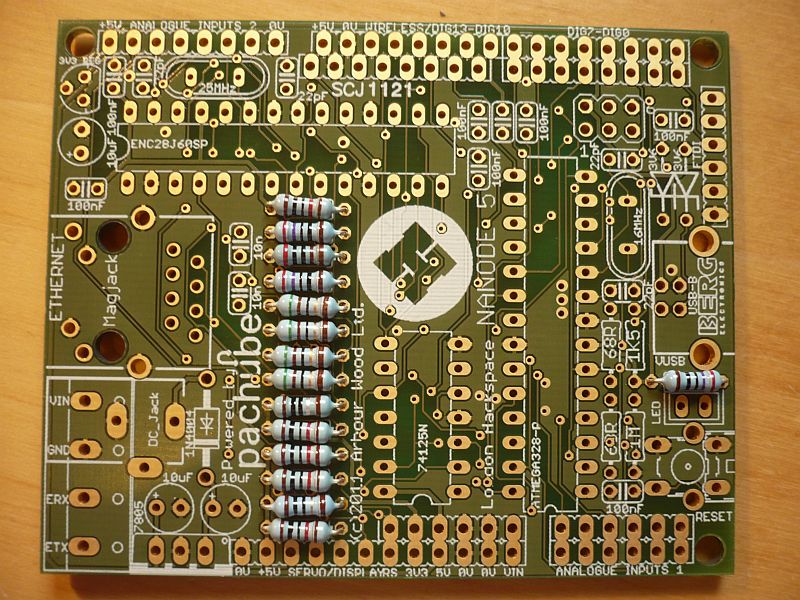

Step 3

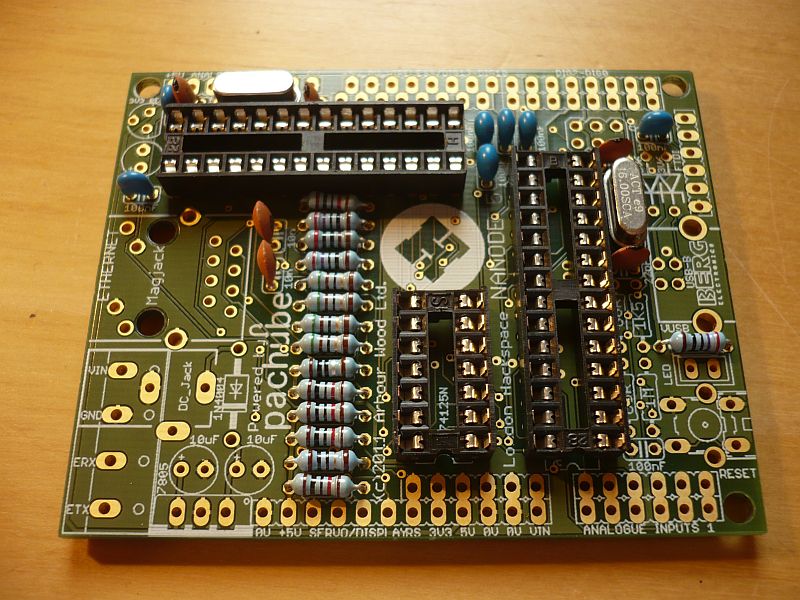

We start with the resistors that make up the central strip. Resistor leads should be bent close to the resistor body within about 1mm.

A tip for doing this without tools - Hold the resistor between thumb and first-finger, and use the other hand to bend the resistor lead over the thumb nail.

Work methodically, - it looks neater if the resistors are all inserted the same direction so that the colour code can be read easily from the left hand side.

First we add the five 10K resistors - the colour code is Brown Black Black Red (The last band on all resistors is Brown).

After you have soldered the five resistors from the underside of the board, cut off the excess leads using side cutters.

Step 4

Now we add the four 51R resistors - the colour code is Green Brown Black Gold.

Step 5

Now we add the three 270R resistors - the colour code is Red Purple Black Black.

Step 6

The remaining 1R, 10R and 2K resistors are added.

1R has the colour code Brown Black Black Silver and is fitted in the position marked "ferrite".

The silver and gold colours look very similar in certain light conditions - if in doubt use a multimeter to check the value before you fit it.

10R is Brown Black Black Gold

2K is Red Black Black Brown

Note - we will not be fitting the two 68R resistors, the 1K5 and the 1M on the right hand side near the USB socket - these are a later virtual USB option - retain them in the kit to be fitted when the software for this option is released.

Step 7

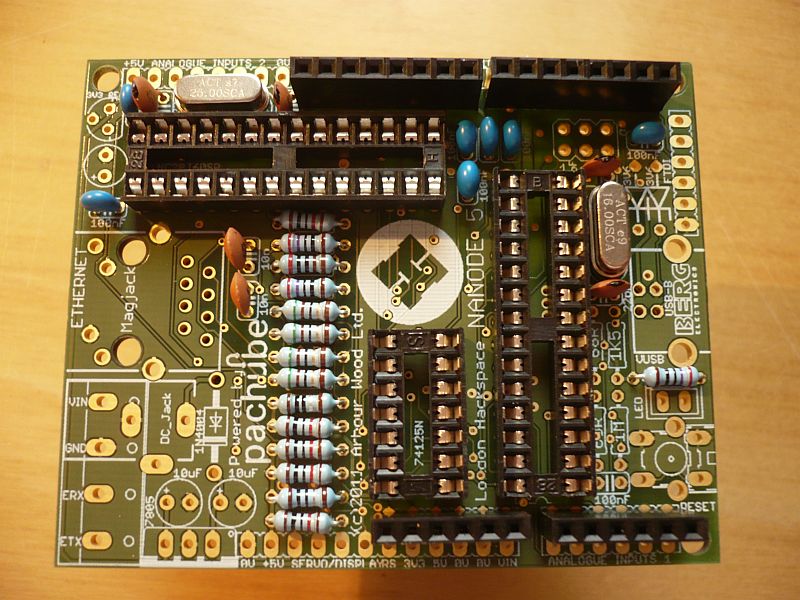

Add the IC sockets making sure that the pin 1 "notch" lines up with the notch in the symbol on the pcb.

It's best to tack diagonally opposite corners to hold the socket in place whilst the rest of the pins are soldered. Make sure they are fitted flat on to the board.

Step 8

Add the four 22pF capacitors marked 22 and with a flash of black paint, and the two 10nF capacitors marked 103

Step 9

Add the 25MHz crystal marked 25.00SCA. Crystals should be inserted so that they are lifted approximately 1mm above the pcb to prevent possibilty of metal can shorting to vias beneath.

Step 10

Add the 16MHz crystal marked 16.00SCA

Step 11

Add the seven 100nF capacitors, colour blue and marked 104. There is a spare location for a 100nF capacitor next to pin 1 of the ATmega328 IC. Do not fit any component in this location - just the seven in the picture.

Step 12

Here is the board so far - more than half way.

Step 13

Solder in the "shield" connectors. There are 2 x 6 way and 2 x 8 way SIL sockets. Make sure you get them in the inner lines of holes and that they are fitted straight and vertical. Best to tack one end pin whilst you hold them straight - check the alignment then solder the remaining pins in place.

Step 14

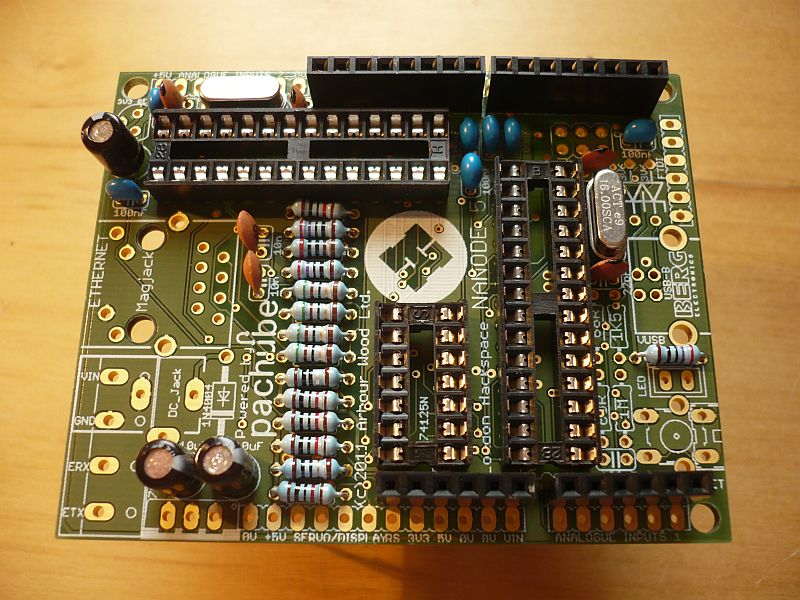

Add the three 10uF electrolytic capacitors - noting that the longer lead is the positive which lines up with the + label on the pcb. You can also confirm the orientation by looking at the position of the white strive (-ve) in the photograph.

Step 15

Add the FTDI header - a 6 way right angled header on the right hand side of the pcb. Make sure it is straight and level.

Step 16

Fit the right angled reset switch

Step 17

Add the 5V regulator as shown and the 4 way screw terminal block. You may need to assemble the two 2 way terminal blocks to make a 4 way - BEFORE you solder to the pcb.

Step 18

Fit the 1N4001 protection diode as shown - noting that the banded end is lined up with the band on the pcb legend

Step 19

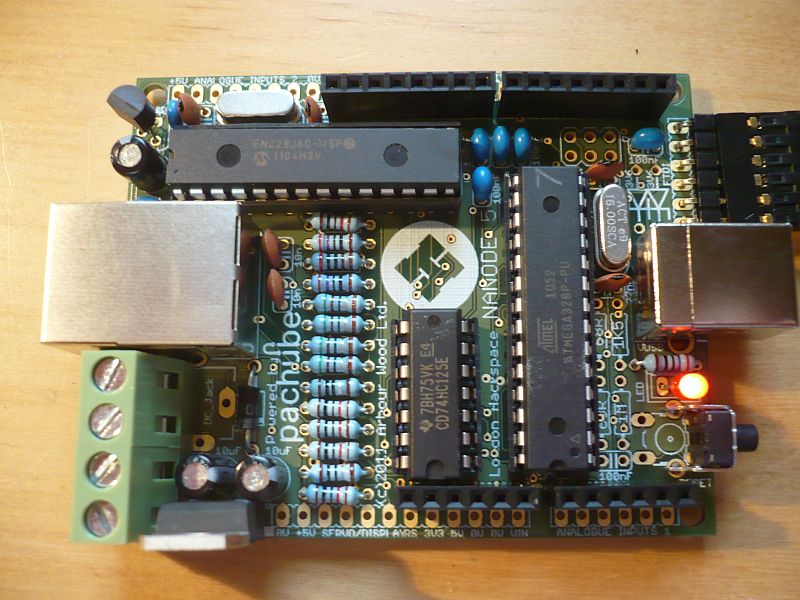

Now - the tricky part. The 3V3 regulator needs to be fitted in a certain way - but not like the pcb symbol. Copy the orientation as in the next 2 pictures.

Step 20

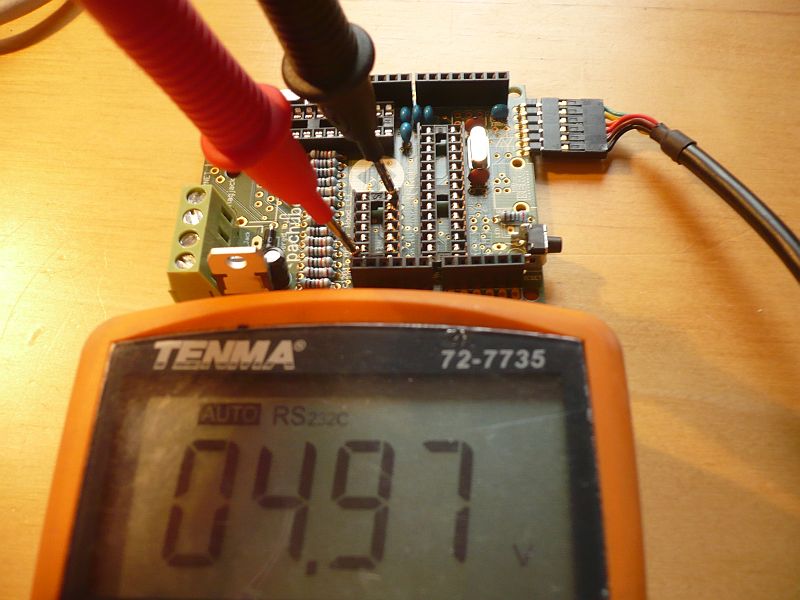

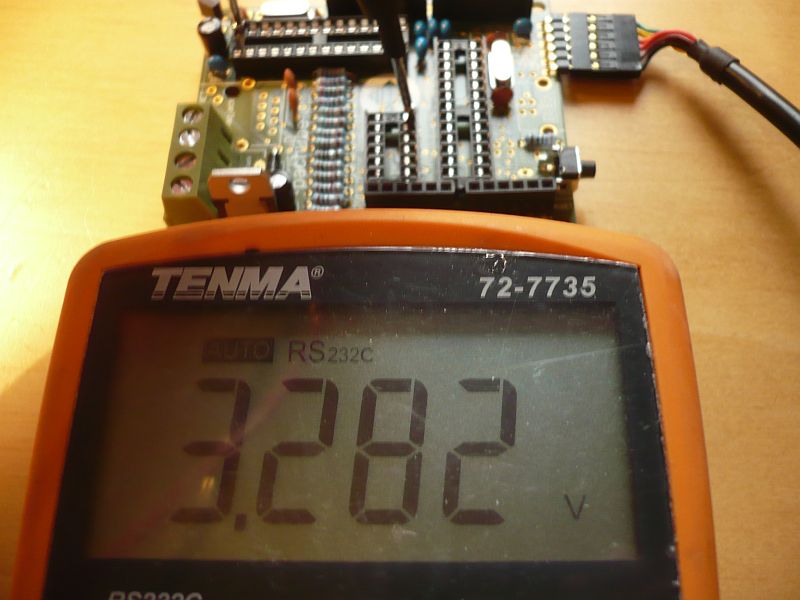

Now we test the board to make sure that the 5V and 3V3 power supply rails are working OK. We do this before we insert any of the ICs (as more than 60% of the kit value is in the ICs and we don't want a premature fry-up).

Put the positive probe of the meter on pin 14 of the 14 way IC socket and the negative probe on pin 7 of the same socket.

Insert the FTDI cable with its black wire closest to the centre of the pcb. Look for a voltage close to 5.00V.

To measure the 3V3, keep the black meter lead on pin 7 of the 14 pin socket and put the red meter probe on pin 28 of the far 28 pin socket as shown. Look for a voltage close to 3.3V

Step 21

If the voltage tests check out - we can fit the remaining parts - the Mag-jack connector, the USB connector and the Red LED.

The Mag-jack has 12 pins, 2 lugs and 2 prongs to insert, and can be a bit tricky. Line it up carefilly and gently push it home. Make sure all the narrow pins have been correctly inserted through their holes.

Solder in place including the 2 metal prongs.

A similar process for the USB B socket.

The Red LED is fitted such that the long leg, the anode, is inserted in the hole closest to the edge of the pcb.

Step 22

Now we come to fit the ICs into their sockets.

Remove the power (FTDI or USB) from the pcb before inserting the ICs!

The ICs can be added - making sure you have the correct position and orientation.

Don't get the ATmega328 and the ENC28J60 in the wrong sockets - as that would be bad, quite bad.

The ATmega328 will be supplied pre-programmed with the bootloader.

Some ICs will have their pins slightly splayed. This can be fixed by pressing the side of the IC firmly against the bench top until the pins are straight and parallel.