Difference between revisions of "Project:PCB Making"

(→Notes) |

(→Notes) |

||

| Line 145: | Line 145: | ||

The UV box, etching tubs and all chemicals are currently in the left hand metal cupboard (marked etching stuff) at the far end of the dirty room. | The UV box, etching tubs and all chemicals are currently in the left hand metal cupboard (marked etching stuff) at the far end of the dirty room. | ||

| − | If anyone in interested in making PCBs and needs a hand, there are now 3 members of the Hackspace that have been etching PCBs in loco - Daniel (dsikar), Solexious and Meurig. Ask any one of them and I'm sure they'll be happy to lend a helping hand. | + | If anyone in interested in making PCBs and needs a hand, there are now 3 members of the Hackspace that have been etching PCBs in loco - Daniel (dsikar), Solexious and Meurig. Ask any one of them and I'm sure they'll be happy to lend you a helping hand. |

== Tried and Tested Settings == | == Tried and Tested Settings == | ||

Revision as of 01:08, 2 September 2010

Project maintained by Daniel Sikar ~/ dsikaratgmaildotcom.

| PCB Making

| |

|---|---|

| QR code |

Project Brief

Summary

How to make a Printed Circuit Board (PCB) using photoresist laminates.

Overview

This howto is intended as a module, aimed at providing building blocks to emulate and extend projects such as the Benito 7, Nanduino and Teensy.

Equipment

There is an ongoing pledge campaign to improve facilities with a better etch tank

Motivation

PCB making autonomy, although not an absolute necessity in this day and age, is helpful.

Once an electronic prototype is working on a breadboard, the next logical step is to firm up all components on a PCB, where they are less likely to come apart.

Bringing electronic designs to life engenders spatial awareness and can also be fun.

The bigger picture

There are several steps in producing electronic devices. PCB making comes in after the artwork is ready to be transferred and before the components are ready to be soldered onto the board.

There are also alternatives to some of the chemical processes - e.g.

Method

The method described consists of exposing, developing, etching, drilling and tinning a photoresist copper-clad board.

Bill of Materials (BOM)

- Photoresist Copper-clad board Maplin product page (code FA61R).

- Sodium silicate Maplin product page (code AP01B). - full bottle purchased 05-Aug-2010

- Ferric chloride Maplin product page (code XX12N).

- Methylated spirits Wickes product page (code 600343).

- Flux pen Maplin product page (code N63AA).

Additionally:

- Scale

- Tubs

- Mixing and storing vessels

- UV exposure box

Recommendation from Imperial College Lab Technician: If you find small specks and holes in the coper then print on normal A4 paper and increase exposure time to 5 mins (as opposed to 12 to 20 seconds with acetate).

- Hammer & punch

- Drill & drill bits

Recommendation from Imperial College Lab Technician: Do not use Tungsten Carbide drills bit with a long shank, they break very quickly. Instead use these with a Dremel and drill press High-speed twist drills with 2.35mm shanks

- Gloves (found under the sink)

Steps in a nutshell

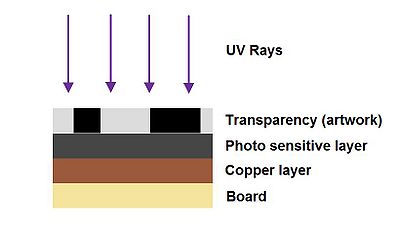

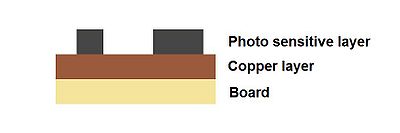

Note in this cross section, black in the transparency layer represents a via (trail) on the left and a pad (where a component pin will be soldered) on the right.

1. The artwork (printed onto a transparency) is placed over the photoresist copper-clad board and exposed to UV light. (8 minutes)

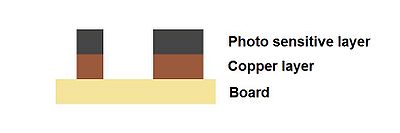

2. The photo sensitive coating weakens as a result of exposure, and is rinsed off with a 10% sodium silicate solution. (1-2 minutes)

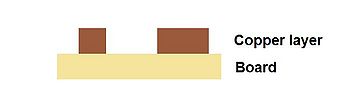

3. Copper-clad board is immersed in a 30% ferric chloride solution until etched. (30-40 minutes)

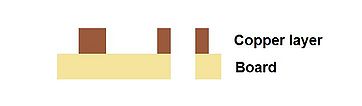

4. Remaining photo sensitive layer is removed with Methylated spirits. This can also be achieved by scrubbing the etched board with wire wool.

5. Board is drilled to allow mounting of Through Hole (TH) components.

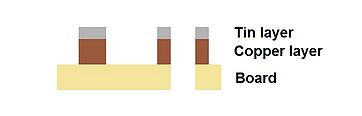

6. Flux is applied to copper, which is then tinned.

An additional step is to coat the finished board with an insulating layer which prevents short circuits in case of conductive objects coming in contact with the copper trails. This can be distinguished by a varnish (often green) finish, seen in commercial PCBs.

Clean up

The chemicals can be returned to their respective bottles, and the small residue in the tubs used in the process should be rinsed out in the sink.

Once spent, the sodium silicate solution can be poured down the drain. The ferric chloride on the other hand, must be taken to a Harzadous Disposal Unit, or, deactivated according to this method.

Real life example

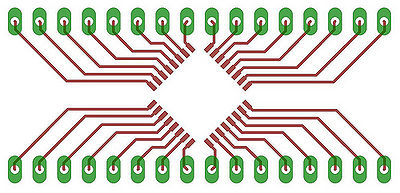

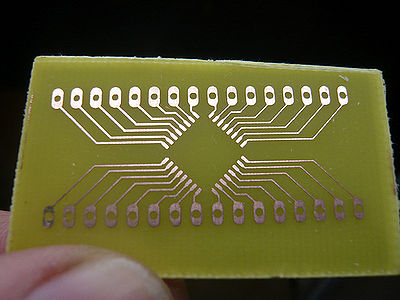

- Artwork, generated by the popular CadSoft Eagle package (.brd file, "top" and "pad" layers shown). The enlarged image represents a TQFP 32 to DIL 32 converter. Print your design reversed so that the printed side of the transparency can be placed next to the board when exposing to UV. Keeping the toner as close to the board as possible means you can achieve better definition on these traces.

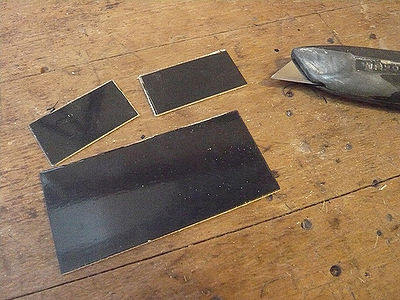

- Cutting board to size, by scoring and snapping.

- Finishing the edges, to ensure good contact between transparency and board. Very important step, if any of the edges are raised the UV light can get under the transparency and you'll lose definition on thin traces.

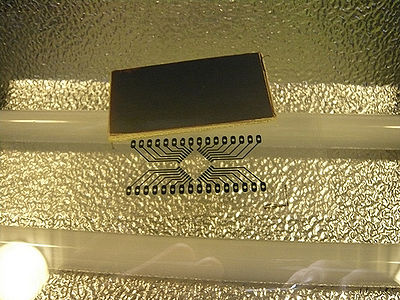

- Preparing for exposure. Double-up transparency for better results, or run through the printer two or three times to put down more toner.

- Peeling off protective layer.

- Expose in the UV box.

- Developing the photoresist in a sodium silicate solution.

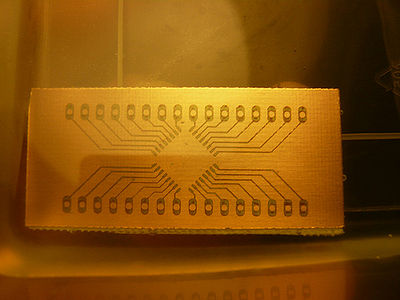

- Etching away the unwanted copper in a ferric chloride solution.

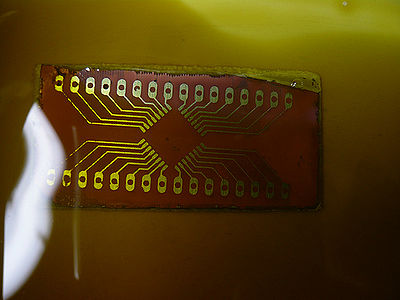

- The etched board.

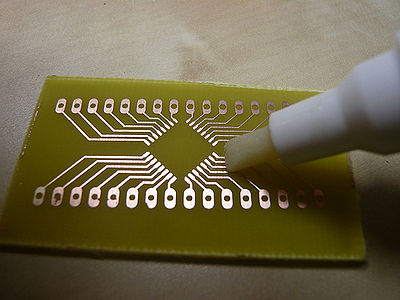

- Applying flux.

- Tinning

TODO

Notes

Artwork can be printed straight onto a transparency sheet, on a laser printer. Alternatively high street print shops will do the job. One run on the laser might not be dark enough, try printing multiple times on the same sheet to lay down more toner.

The board was drilled on the Dremel Workstation. Drill bit; 0.7mm (smallest one) on the workstation plastic drill case, chuck is in the silver dremel case. [I couldn't find a suitable drill bit or chuck, or silver dremel case for that matter...]

The UV box, etching tubs and all chemicals are currently in the left hand metal cupboard (marked etching stuff) at the far end of the dirty room.

If anyone in interested in making PCBs and needs a hand, there are now 3 members of the Hackspace that have been etching PCBs in loco - Daniel (dsikar), Solexious and Meurig. Ask any one of them and I'm sure they'll be happy to lend you a helping hand.

Tried and Tested Settings

Meurig - 04-Aug-2010

- Laminate: transparency 'borrowed' from work, run through a laser printer three times on enhanced quality mode, black and white (obviously).

- Board: Maplin SRBP Pre-Sensitised Copper-Clad Board [JP56L]

- Exposure time: Warmed up the UV unit for 2 mintues before starting, then exposed board for 2.5 minutes. Took some care to be quick between peeling and exposing, but wasn't anal about it.

- Developing solution: Maplin Universal PCB Developer [AP01B] made up by eye to approx 10%? was made up by Oni the night before so I'm not sure. Very much room temperatures.

- Developing time: Took about a minute, was really obvious that it was working.

- Etching solution: Maplin clear etchant, I can't find it on the website but it wasn't ferric chloride, again made up by Oni the night before so room temperature.

- Etching time: This took a while, went much faster if I was agitating the solution. Somewhere between 20 and 40 minutes (I was having dinner so didn't really keep track). Heating the solution might speed this up but I wouldn't really want to put in the microwave.

- Removing exceess photoresist: I hadn't read the thing above about white spirit so I just exposed the whole board again (without laminate) for about a minute and ran it through the developer again, worked well but I'll try white spirit next time.

- Protective layer: I just covered the whole board with a flux pen (donated by

AdrianFarnell, left by the box of sharpies).

- Addendum: My first board was ruined by leaving a lip where I'd cut it (hacksaw). Always make sure the board is perfectly flat! I left some developer and etchant in the trays since I'm sure they'd by good for a few more runs and I wasn't sure how to dispose of them.