Project:Flow Hood

Overview

A Laminar Flow Hood would enable us to greatly improve the aseptic technique protocol in the hackspace. But first we need to make one.

Basic design

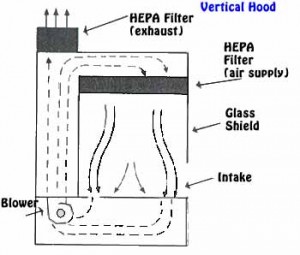

We should aim to build a vertical flow hood as that not only protects cultures from contamination but protects the user from the cultures being worked on.

Here is a basic diagram of what it should look like.

Construction and Materials

Frame

We need to construct a frame: perhaps weld together some steel box section; or chop up and repurpose an old shelving unit; or construct it out of makerbeam, openbeam or easy fix.

Work surface and side panels

Because we will be using 70% ethanol for sterilisation, the materials used for the sides and work surface must be resistant to this. Unfortunately 70% ethanol kills perspex over time so it looks like we will need to use glass for the sides and perhaps a sheet of stainless steel for the work surface.

Filters

HEPA rated filters will remove any bacteria and other contaminants from a flow of air. They are often used in air conditioners and air purifiers. The entire 'ceiling' of the flow hood must consist of filters, so the dimensions of worksurface of the hood are constrained by what size filters we can find for a reasonable price. So far these filters on Amazon appear to be our best option - we can put two next to each other to achieve a 64x42cm work surface.