Project:PCB Making: Difference between revisions

Danielsikar (talk | contribs) |

Danielsikar (talk | contribs) |

||

| Line 76: | Line 76: | ||

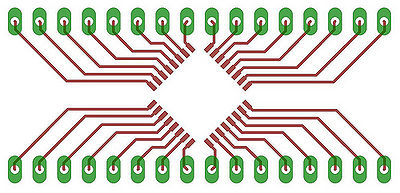

* Artwork, generated by the popular Eagle Cadsoft package (.brd file, "top" and "pad" layers shown). It can be printed straight onto a transparency sheet, on a laser printer. Alternatively high street print shops will do the job. | * Artwork, generated by the popular Eagle Cadsoft package (.brd file, "top" and "pad" layers shown). It can be printed straight onto a transparency sheet, on a laser printer. Alternatively high street print shops will do the job. | ||

[[File:TQFP32_DIL32_EagleBRDFile.jpg]] | [[File:TQFP32_DIL32_EagleBRDFile.jpg|400px]] | ||

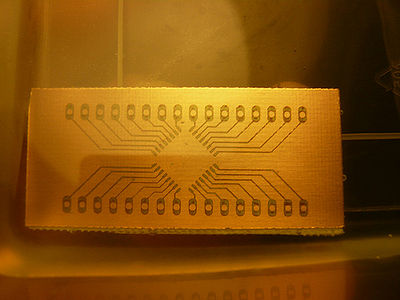

* Developing the photoresist in a Sodium Silicate solution. | * Developing the photoresist in a Sodium Silicate solution. | ||

[[File:TQFP32_DIL32_PhotoresistDevelopment.jpg]] | [[File:TQFP32_DIL32_PhotoresistDevelopment.jpg|400px]] | ||

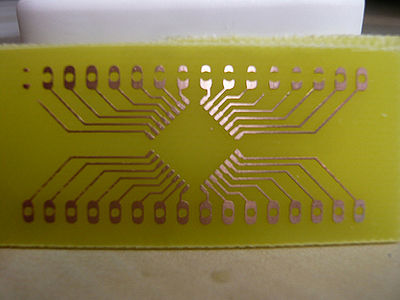

* The etched board (with some flaws). | * The etched board (with some flaws). | ||

[[File:TQFP32_DIL32_Etched.jpg]] | [[File:TQFP32_DIL32_Etched.jpg|400px]] | ||

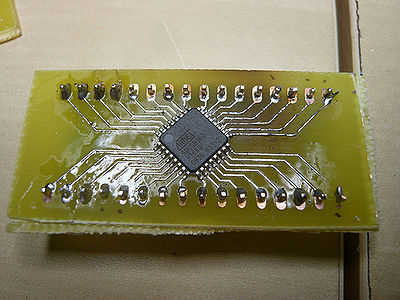

* Final assembly (in progress). | * Final assembly (in progress). | ||

[[File:TQFP32_DIL32_Assembled.jpg]] | [[File:TQFP32_DIL32_Assembled.jpg|400px]] | ||

== Notes == | == Notes == | ||

Revision as of 22:55, 16 April 2010

Project maintained by Daniel Sikar ~/ dsikaratgmaildotcom.

Project Brief

Summary

How to make a Printed Circuit Board (PCB) using photoresist laminates.

Overview

This howto is intended as a module, aimed at providing building blocks to emulate and extend the Nanduino project.

Motivation

PCB making autonomy, although not an absolute necessity in this day and age, is helpful.

Once an electronic prototype is working on a breadboard, the next logical step is to firm up all components on a PCB, where they are less likely to come apart.

Bringing electronic designs to life engenders spacial awareness and can also be fun.

The bigger picture

There are several steps in producing electronic gadgets. PCB making comes in after the artwork is ready to be transferred and before the components are ready to be soldered onto the board.

Method

The method described consists of exposing, developing (etching), drilling and tinning a photoresist copper-clad board.

Bill of Materials (BOM)

- Photoresist Copper-clad board Maplin product page (code FA61R).

- Sodium Silicate Maplin product page (code AP01B).

- Ferric Chloride Maplin product page (code XX12N).

- Methylated spirits Wickes product page (code 600343).

- Flux pen Maplin product page (code N63AA).

Additionally:

- Scale

- Tubs

- Mixing and storing vessels

- UV exposure box

- Hammer & punch

- Drill & drill bits

Steps in a nutshell

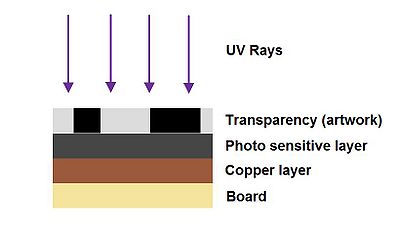

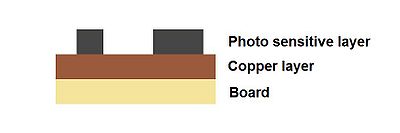

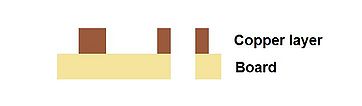

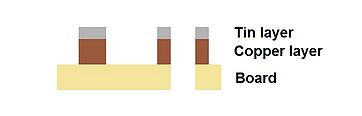

Note in this cross section, black in the transparency layer represents a via (trail) on the left and a pad (where a component pin will be soldered) on the right.

1. The artwork (printed onto a transparency) is placed over the photoresist copper-clad board and exposed to UV light.

2. The photo sensitive coating weakens as a result of exposure, and is rinsed off with a 10% Sodium Silicate solution.

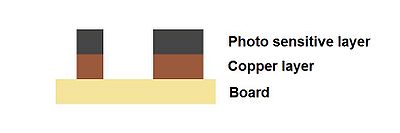

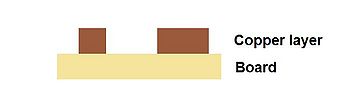

3. Copper-clad board is immersed in a 30% Ferric Chloride solution until etched.

4. Remaining photo sensitive coating is removed with Methylated spirits. This can also be achieved by scrubbing the etched board with wire wool.

5. Board is drilled to allow mounting of Through Hole (TH) components.

6. Remaining copper is tinned with a Flux pen, to facilitate soldering and prevent oxidation.

An additional step is to coat the finished board with an insulating layer which prevents short circuits in case of conductive objects coming in contact with the copper trails. This can be distinguished by a varnish (often green) finish, seen in commercial PCBs.

Real life example

- Artwork, generated by the popular Eagle Cadsoft package (.brd file, "top" and "pad" layers shown). It can be printed straight onto a transparency sheet, on a laser printer. Alternatively high street print shops will do the job.

- Developing the photoresist in a Sodium Silicate solution.

- The etched board (with some flaws).

- Final assembly (in progress).

Notes

The board was drilled on the Dremel Workstation. Drill bit used was the smallest one, held in a bit of cardboard, in the black Dremel box. Alternatively, a 0.67mm drill bit should do, though there is not a chuck in the Hackspace to accomodate.

The UV box is currently living under the XBox, on the shelf nearest to the scope.

The chemicals and tubs are on the shelf next to the coffee maker.

If anyone in interested in making PCBs and needs a hand, let me know.