Equipment/PCB etch station: Difference between revisions

No edit summary |

No edit summary |

||

| Line 136: | Line 136: | ||

The tank was previously in a school and there is a laminated sheet with usage instructions. It may not be applicable to our use but is worth looking at. | The tank was previously in a school and there is a laminated sheet with usage instructions. It may not be applicable to our use but is worth looking at. | ||

* [[pcb etching instructions]] | * [[pcb etching instructions]] - '''This is the canonical guide to etching PCBs at LHS!!''' | ||

=== External references === | |||

* [http://www.megauk.com/datasheets/5285_Data_Sheet_PB_BENCH_Line_and_PCB_Labstation_instructions.pdf Manufacturer's instructions] ([[Media:PB BENCH Line and PCB Labstation instructions.pdf|local copy]]) | * [http://www.megauk.com/datasheets/5285_Data_Sheet_PB_BENCH_Line_and_PCB_Labstation_instructions.pdf Manufacturer's instructions] ([[Media:PB BENCH Line and PCB Labstation instructions.pdf|local copy]]) | ||

* [http://www.megauk.com/datasheets/5320_Data_Sheet_Fitting_Instructions_for_Heater_and_Bubble_Bar.pdf Heater and bubble bar Maintenance] - also see Mike's posting on mailing list. | * [http://www.megauk.com/datasheets/5320_Data_Sheet_Fitting_Instructions_for_Heater_and_Bubble_Bar.pdf Heater and bubble bar Maintenance] - also see Mike's posting on mailing list. | ||

| Line 146: | Line 148: | ||

* [http://www.megauk.com/cgi-bin/mega/datasheets.pl All Mega MSDS and data sheets] | * [http://www.megauk.com/cgi-bin/mega/datasheets.pl All Mega MSDS and data sheets] | ||

* [http://rdchem.com/chemical-milling.html Maintaining ferric chloride etchant] | * [http://rdchem.com/chemical-milling.html Maintaining ferric chloride etchant] | ||

[[Category:PCB making]] | [[Category:PCB making]] | ||

Revision as of 21:48, 15 June 2014

| PCB etching station | |

|---|---|

| |

| Model | PCB710S |

| Sub-category | Fabrication |

| Status | Good working order |

| Consumables | Cupric Chloride, Developer |

| Accessories | Pump |

| Training requirement | no |

| Training link | Etching instructions |

| ACnode | no |

| Owner | Artag |

| Origin | Pledge |

| Location | Basement, ante-room beside lift |

| Maintainers | Artag, Mentar |

We have a Mega Electronics PB710S PCB Production line etching station, obtained by a Pledge

Note : see Pcb for other references

Important Warnings

- CLEAN UP AFTERWARDS

- Do not run any heater unless the tank is full of liquid. It should blow a thermal fuse before melting the tank, but that may involve replacing the heater. Keep unused heated tanks full of plain water or disable the heaters by unplugging the associated connector inside the cupboard door.

- Do not etch anything except copper (other metals will pollute the etchant).

- Do not drink the contents, even when there's no beer.

- Do not allow children or drunken hackers to play with the tanks.

- Check the power has been turned off after use.

- Do not dip a basket soaked in one chemical into the tank of another chemical.

- Read the instructions (pdf)

- CLEAN UP AFTERWARDS

Less important warnings

- You normally place boards to be etched in the plastic basket under a tank lid, then dip it into the tank. If the PCB is too close to the open end, it will fall out. You may have to drain the tank to retrieve it. You don't want to do this, so put the pcb well into the opening and don't tip it forwards as you remove the basket from the tank.

- Very small PCBs may fall through the holes. A possible solution is to put them in fine-mesh envelopes before putting them in the basket. Finding a suitable envelope is left as an exercise for the user (hint - look on the Mega website).

Model

- Make: Mega Electronics

- Model: PB710S - PCB 7 tank production line with sink

Manual: File:PB BENCH Line and PCB Labstation instructions.pdf

Controls

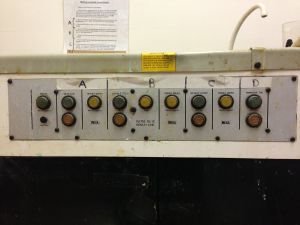

The leftmost button on the control panel is mains power. If you see it lit up when no-one is using the tank, please turn it off (but if someone _might_ be waiting for it to warm up, please check first!). Probably a good idea to switch off at the mains as well.

Each tank and rinser then has a control section. Working from left to right, these are:

- Developer - Heat button and 'heater active' light. Set to about 28°C. Heating not normally required.

- Developer rinse - Spray button activates spray bar.

- Etch - Heat button and 'heater active' light. Set to about 48°C. Takes about 15-20 minutes to get hot.

- Air bubbler button - only active when heating is also on.

- Etch rinse - Spray button activates spray bar.

- Photoresist stripper - Heat button and 'heater active' light. Set to about 50°C. Optional.

- Stripper rinse - Spray button activates spray bar.

- Tinning - Heat button and 'heater active' light. Set to about 50°C. Optional.

The spray bars work best if only one is on at a time (and unless you're making a lot of boards at once, you probably only need one).

Status

1st Tank - Developer

Working (powder, fresh as of 06-DEC-2012) {is this still the case?}

Resupply with:

2nd Tank - Etchant

Now contains CuCl2 etchant at ~3M strength. Ready to use. (Heater does not seem to shut down by itself so make sure not to overheat the solution, being worked on)

Resupply: instructions below! Required materials are:

- HCl

- Copper

- NaOH (for checking concentration)

DO NOT put Ferric Chloride in this tank !!! In fact, please don't use ferric chloride at all - it silts up the tank and is really difficult to clean up. If there is some reason why we wish to use it again, it may be possible to use the 4th tank for it.

CuCl2 Etchant

The bath for Cupric Chloride etch was prepared using the slow method : leave some copper in acid, allow corrosion to occur generating some oxides, add further copper and acid as required. Water, acid, copper and hydrogen peroxide (if used) should be noted as it's easy to over-dilute if you just add stuff randomly.

The preparation so far contains 540g copper, 2900ml 38% HCl, 1750ml water. SG is 1260. This is ready for use - air has been bubbled through it and it has reached the bright green colour indicating it has converted copper to cupric chloride. The acid concentration appears to be correct and I have reconnected the heater. If the etchant is not bright green, please leave the small fishtank bubbler running. The bubbles will regenerate the etchant.

DO NOT ETCH ANYTHING EXCEPT COPPER IN THIS TANK

See File:CuCl.pdf for maintenance instructions. These are basically : Check colour. Bubble if dark. Titrate against 1 molar NaOH to check acid concentration (this only requires a check for precipitate, no need for acid indicator). Add HCl if necessary.

If you use it, don't rely on the small bubbler to provide agitation - keep it moving the whole time (and be careful your board doesn't walk out the end of the basket when you do that). The small bubbler is really only there to re-aerate the solution after use, as it's quiet enough to leave on.

3rd Tank - stripper

Working. (No not THAT kind of stripper you dirty minded geek!)

Resupply with

- Mega Electronics 600-019 PC155 Resist Strip 1 Ltr makes 5 Ltrs

- Rapid 34-0400

4th Tank - (Water)

Currently contains clean water (mainly to protect the heater if accidentally switched on

Planned changes

Use Cupric chloride in the etch tank rather than Ferric chloride, which is messier, requires frequent replacement and silts up the bubbler.Has been done- Replace the bubbler in the bottom of the tank with a bar suspended from the basket, so that it's easier to clean.

- Link both the large air pump and the small one into the same air supply so the cupric chloride can easily be regenerated (requires long slow bubbling rather than short fast bubbling)

- It would be nice to have power without using the extension lead. The existing ring main might be extended fairly easily to put sockets on the wall near the sink.

Notes

The pump was replaced with a heavier duty medical unit mostly because it was cheap & available. The original was a fishtank pump and is still mounted on the front of the tank. It worked, but seemed not to have enough pressure available to overcome backpressure if the aeration tube had partly filled with etchant. Fitting it involved a few peculiarities, though.

- There is a clamp on a branch of the tube near the pump, which can be used to restrict a controlled pressure relief and hence the vigor of the bubbles.

- The pump is no longer fitted to the tank, but instead rests in the cabinet

- It is still possible to remove the tank for maintenance: the cable and pipe connecting to the pump are very long but if they need to be detached the cable can be unplugged from the back of the pump and the pipe unplugged from the pump.

- There is now a one-way valve between the pump and the antisyphon trap to reduce the possibility of etchant flowing into the pump.

- The power connection to the pump has no earth wire connected and apparently swaps black/white colour coding. This is not just carelessness : the original black/white wiring apparently had black as neutral, white as live to the fish tank pump. The IEC lead to the new pump uses conventional euro colours : black is live. So black and white swap at the join. It's not very important as the pump doesn't have a preferred live connection.

- The earth pin in the cable to the pump is not connected at the pump end (it's a 2-pin connector) so there was no point connecting it at the tank end.

The piping requires some care. Because of the increased pressure available from the pump, if the bubbler is blocked it's possible for the pump to blow the pipe off the bubbler. This can then lead to etchant leak.

At present, there are cable ties around the most important joints but NOT where it links to the pump. This tends to result in that joint breaking rather than any other, which is good because it's easily accessible and doesn't cause leaks. If there are problems with it blowing off too regularly, look into the cause : just fitting it more solidly is likely to lead to etchant leaks.

Originally, I restricted the airflow into the tank (to avoid excessively vigorous bubbles) by pinching the air tube with a clamp. This often caused the pump connector to come off, prompting the use of cable ties. When the bubble tube silted up, it was that joint that came undone instead of the pump joint. This was a bad thing.

A new configuration places a T joint near the pump with the clamp fitted to the additional open outlet. The idea is to make a controlled leak so that excess pressure is bled off rather than overpressurising the joints. It's likely that this will need to be adjusted as the bubbler silts up.

The low-volume pump used for aeration is now teed into the bubbler pipe, so it will either bubble slowly from that or fast from the big pump. I had to add another non-return valve so the aerator air didn't all leak out the restricted leak. { diagram needed }

Instructions

The tank was previously in a school and there is a laminated sheet with usage instructions. It may not be applicable to our use but is worth looking at.

- pcb etching instructions - This is the canonical guide to etching PCBs at LHS!!

External references

- Manufacturer's instructions (local copy)

- Heater and bubble bar Maintenance - also see Mike's posting on mailing list.

- Ferric Chloride

- Stain remover

- Fine etch crystals - we don't use this at present but it's been suggested.

- Photoresist stripper

- Tin plating - We have a small tub of this, possibly unusably old.

- All Mega MSDS and data sheets

- Maintaining ferric chloride etchant