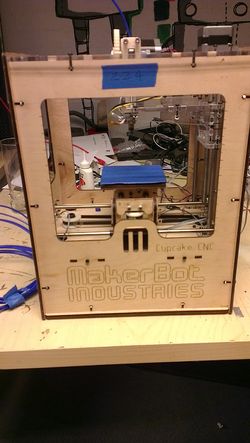

Project:Cupcake-o-Matic

The Makerbot Cupcake CNC was Makerbot's first foray into the 3D printer kit market, and one of the first 3D printer kits on that market. The Cupcake CNC takes a lot of it's design cues from 2 sources, the initial reprap 3D printer, Darwin, and the other from the need to make it laser cut-able.

It was followed by the Thing-o-Matic which fixed many of the problems associated with the Cupcake CNC.

The Start

I bought a Cupcake CNC in September 2009. I received Cupcake 224 from batch #6. I quickly assembled it and attempted a test print all in about 24 hours. It did not work. I could not get it to extrude plastic through the MK4 Plastruder reliably, when it did extrude I could then not get it to stick to the acrylic build platform. I left it be for a couple of years annoyed with what seemed a wasted purchase until January 2012 when I bought a MK5 drive gear from KD85, the closest European distributor. I also added a heated build platform to my order to ensure the extrusion would stick to the bed.

These two upgrades allowed me to start printing reliably and I immediately started printing a new extruder to improve the MK4 plastruder. I was aiming to replace it with a stepper motor driven one so as to improve the build quality with a better model slicer such as Slic3r. I ended up printing out multiple extruder bodies as I repeatedly printed the wrong ones.

One good side affect of this was that I also ended up printing out the rest of the Huxley Pro parts to match the NEMA14 extruder body. A friend of mine has suggested he may find a use for it.

This vast amount of printing soon left me with very little of the 1lb natural ABS spool I received with the kit. I decided to buy some blue PLA as I through it would be the ideal choice for future printing. Not exactly.

The Present

I have made the following modifications to my Cupcake CNC:

Updating the Electronics

Replaced all the Makerbot Generation 3 Electronics with a Sanguinololu v1.2+ board

Adding a Cantilever Z Axis

Replaced the 4 threaded rod suspended Z axis with a Thing-o-Matic inspired cantilever stage.

Improving the Power Supply

Replaced the 300W PC power supply with a 12V 30A Power supply (may be further replaces with a smaller PSU)

A Better Extruder

The Makerbot Cupcake CNCs from batch 6 came with a laser cut Plastruder MK4. To drive the filament a T2.5 timing belt gear was used, it had 17 teeth which would bite into the filament, however the teeth were blunt so could not get a good grip on the filament reliably. This lead to the extruder jamming mid way through a print. When the Plastruder MK4 came out it was a new design but it was quickly superseded by improvements from the RepRap project.

These improvements took the form of the Wade's Geared Extruder, a simplified version of Adrian's Geared Extruder. The Wades extrider is notable for it's use of a single mounting block, a stepper motor, two gears and an idler assembly.

Replaced the MK4 Plastruder with a Gregs Modified Wade Extruder. Replaced the nichrome wire on the hot end with a heater block and power resistor.

However after all these modifications I must still get this printer working and am currently attempting to tune this configuration into a working printer.

I made my first semi-successful print today (10th September 2012), it was meant to be a 10mm cube but turned into a 10x7x6mm splodge. It would appear that the extruder is not biting into the filament and occasionally strips the filament. It also appears that I have the values for steps per millimeter incorrect for the Y and Z axes.

Further calibration is required.

The Future

I'd like to add a few more upgrades to this "Cupcake-o-Matic" in the future namely:

- Add an LED ring around the hot end so as to easily see what is happening.

- Add a webcam mount for videos or remote printing.

- Affix end stops to allow for automated homing.

- Exchange the Z axis drive with a lead screw instead of M8 rod (possibly TR8x1.5).

- Tune the whole 3D printer for quieter printing.

At the moment I view 3D printing akin to Linux. In order to be working on the cool parts you MUST have a rock solid back up machine so that you can rescue the cutting edge machine when needs be. I want my Cupcake-o-Matic to be my back-up machine.