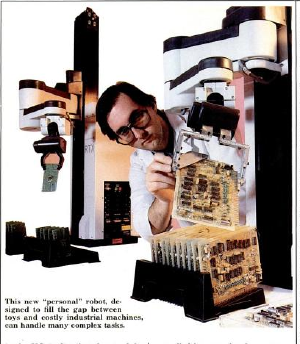

Project:UMI RTX Robot arm

| UMI RTX Robot arm | |

|---|---|

| Created | 23/08/2012 |

| Members | Mentar |

| QR code | |

6 DOF robot arm from 1986, donated by Daithi (he even got the caps that blew!).

It's part of the hackspace and collaborators are welcome, please get in-touch with Mentar (IRC) to find out what you can help. It's a great learning exercise for:

- robotics (surprise!)

- ROS

- arduino

- motor control

- optical sensor control.

Design

- 7 24VDC motors, 20w (3A) for Z axis and 3w (750mA) for the rest

- Each motor has two phase optical incremental encoder

- Arduino Mega 2560 has been kindly donated to the project by tgreer

What's been done

Some of us are working on getting the arm working for the HSRDP project. The plan is to integrate it with ROS package and an make a URDF model for the arm. This will allow it for general robotic use, i.e. someone can create the ROS nodes for a robotic barman, simulate it and then send it to the bot to perform

Might have to replace the control board electronics with a ... wait for it... a Raspbery Pi (well and an Arduino ofcourse)! :D But if someone wants to restore the stock electronics I will avoid hacking the old control board up in-case you want to have a go!

People involved

This is a hackspace project and members are encouraged to participate

| Mentar | Coordinating, tantalum caps, power-supply (with Asoko's help),the elbow pulleys, clean-up |

| Tmylk | Motor control |

| jasperw | Diagnosing issues with the elbow joint, clean up |

| pepelisu | Tracing and working on the optical rotary encoder inputs |

| tgreer | Tried to get the z-axis moving, from the output end of the gearbox! Donated Arduino Mega for the project |

Work to do

- Design an arduino based board to replace the ancient control board

- 6 pwm channels outputs (bi-directional, optionally with current sensing) tmlyk

- 6 interrupt inputs (dual optical encoders on each joint, half rez) pepelisu

- Replace the broken cover on the elbow-to-wrist with a new one

- Sand down and repaint!

Updates

Update 12/06/2013

Mentar: We've figured out the pinouts on the Z-axis control board, a basic URDF model has been created. Discussed handling of the interrupts by the arduino and PID control.

Update 03/06/2013

Mentar: All traced! With Pepelisu we found out that the problem was in the ribbon cable that we've promptly replaced. He is now doing the part sensing part for the motors and tmlk is making the motor drivers.

Update 28/05/2013

Mentar: Fixed the elbow joint, had to drill a jammed screw off. Traced out about half of the wires from the blue cable, which control all the rotary joints

Update 16/03/2013

Mentar: After attempting to talk to the arm over the serial using different software that's list on this page I got no response of any kind from the arm. Given the state of the RS232 port on the arm I then made sure that all the relevant pins (only 9 are used) rang through to the board. At this point I'm giving up on the control board. I'll start checking the motors and encoders with aim to make a new board from scratch. If anyone wants to have a go at restoring the old board feel free! (I'll try to make an in/out replacement)

Update 07/03/2013

Mentar: Turns out the motor power light didn't go on often due to the fact that the emergency stop contact was rubbish due to the corroded 9-pin D-sub female connector. For the testing phase I've shorted the 2 pins internally, though these would be undone when the arm is to be used. Next step is to connect it up to the and try the talking to it with the software that tgreer found. I have doubts the rusty serial socket works however, so will probably need more repairing.

Update 05/03/2013

Mentar: after taking the power supply apart with Aaron, we found that the problem was with the actual switch, the contacts on it were somewhat corroded resulting in a bad connection. That has now been fixed and the arm powers up. The motor power LEDs are a finicky, and the green button light doesn't always go on when asked. But it remains stable once it does. Next step would be to open up the manual and try to talk to it!

Update 08/01/2013

Mentar: replaced daithi's cap, as only one was blown. Still no luck, the power supply is making a sparky noise even when no external load is attached to it. The red and green motor LEDs go on and then fade out. Opened the power-supply but there is nothing obviously wrong with it despite some areas of corrosion. Didn't have enough time to take it fully out of the enclosure to check the back of the board. Next time I'm in I'll take the board app-art and test it further possibly re-soldering it.

Update 02/10/2012

daithi got the caps, but would like an interested party to try replace them. He's not getting more if the blow again!

Update 27/09/2012

Now that the z-axis works again daithi will try replacing the caps that blew up and see if he can bring the original board back to life

Update 11/09/2012

artag, jasperw and mentar took the arm apart to figure out the problem with the z-axis. Turns out it's not that bad, turns fine. The z-axis motor (24V) wasn't working because of the corrosion layer on the commutator, cleaning the brushes and rotating the motor axle cleaned off some of the corrosion and it works beautifully at 24v

Update 29/08/2012

Tomw and tgreer tried to get this running but the z axis seems to be rusted to f***. The PSU outputs the correct voltages but when trying to put this into "green mode" it buzzes and sticks in red.

Checked fuses and they're ok.

We forced the z-axis to try and break it out of any rusted stickiness and managed to move it down. We also tried 12-24v across the z axis motor and got no response

One of the fuses then blew which we replaced and promptly blew the 5 tantalum capacitors near the right hand connector on the main board. These will need replacing

note: (artag) tantalum capacitors of this age have a tendency to die by going short-circuit. If the fuse allows it, they will then burn up fairly vigorously. Depnding on which ones died, you might be able to ignore this (once they've burnt open-circuit) but it would be best to replace the lot. There are about 4 1uF 35V, about 8 10uF 35V, and 1 47uF 35V.

Reverse engineering

5 of the joints are controlled via an ide like cable, light blue in color, pinouts below

| 1 | Wrist left (roll left + pitch) motor + |

| 2 | Wrist left (roll left + pitch) motor - |

| 3 | Wrist right (roll left + pitch) motor + |

| 4 | Wrist right (roll left + pitch) motor - |

| 5 | wrist yaw motor + |

| 6 | wrist yaw motor - |

| 7 | shoulder yaw motor + |

| 8 | shoulder yaw motor - |

| 9 | elbow yaw motor + |

| 10 | elbow yaw motor + |

| 11 | gripper motor + |

| 12 | gripper motor - |

| 13 | VCC for wrist |

| 14 | VCC for shoulder and elbow |

| 15 | VCC for shoulder and elbow |

| 16 | GND |

| 17 | GND |

| 18 | GND |

| 19 | left wrist ch1 |

| 20 | left wrist ch2 |

| 21 | right wrist ch1 |

| 22 | right wrist ch2 |

| 23 | wrist yaw ch1 |

| 24 | wrist yaw ch2 |

| 25 | shoulder ch1 |

| 26 | shoulder ch2 |

| 27 | elbow ch1 |

| 28 | elbow ch2 |

| 29 | gripper ch1 |

| 30 | gripper ch2 |

| 31 | ? |

| 32 | ? |

| 33 | ? |

| 34 | ? |

| 35 | ? |

| 36 | ? |

| 37 | ? |

| 38 | ? |

| 39 | ? |

| 40 | ? |

Z axis has it's own control board with an L298 driver

| 1 | ch 2 |

| 2 | GND (encoder) |

| 3 | ch 1 |

| 4 | VCC (encoder) |

| 5 | PWM |

| 6 | Direction, + up, - down (11.87 resistor) |

| 7 | GND (control logic) |

| 8 | VCC (control logic) |

| 9 | NC |

| 10 | NC |

Docs

Misc

iBot has one of these in store at Reading Hackspace , it is an RT100 not an RTX, but he thinks they are very similar. He's offered to help with info and also has some more documentation about internals and protocol if needed. Also has some bad C# code he wrote to drive it.