Difference between revisions of "LBL04006"

m |

|||

| Line 16: | Line 16: | ||

|} | |} | ||

'''1. Purpose''' | '''1. Purpose''' | ||

| − | This describes the operation of the Melag EuroKlav 29V-S. The autoclave is used for two main procedures:<br> | + | This describes the operation of the Melag EuroKlav 29V-S. The autoclave is used for two main procedures with respect to GMO deactivation:<br> |

| − | i) sterilization of | + | i) sterilization of glassware and equipment for reuse |

| − | ii) Deactivation of | + | ii) Deactivation of small volumes of GMO exposed media, and GMO exposed waste and equipment. |

| + | iii) | ||

'''2. Scope''' | '''2. Scope''' | ||

| Line 51: | Line 52: | ||

7.1 Daily Test procedure | 7.1 Daily Test procedure | ||

| − | Before using the autoclave for GMO deactivation, the operator should run a test strip through the autoclave to check that it is working to specification. | + | Before using the autoclave for GMO deactivation each day, the operator should run a test strip through the autoclave to check that it is working to specification. |

The test strip should be stapled into the lab book, with a note indicating the operator and the date/time the test was run, along with any observations. | The test strip should be stapled into the lab book, with a note indicating the operator and the date/time the test was run, along with any observations. | ||

| − | 7.1.1 | + | 7.1.1 Unwrapped equipment and glassware with no internal cavities can be sterilized using the Quick Programme (28 psi/134 C/3 mins) |

| + | |||

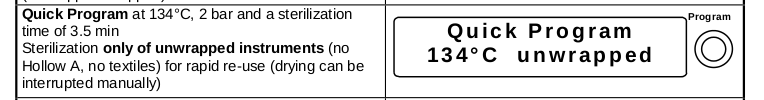

| + | [[File:Screenshot-quick-programme.png]] | ||

| + | |||

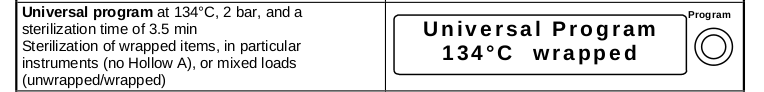

| + | 7.1.2 Materials such as a solid and liquid media can be sterilized using the Universal Programme (28 psi/134 C/30 mins) | ||

| + | |||

| + | [[File:Screenshot-universal-programme.png]] | ||

| + | |||

| + | 7.1.3 Large volumes of liquid or solid media should be processed with extra care. | ||

| + | |||

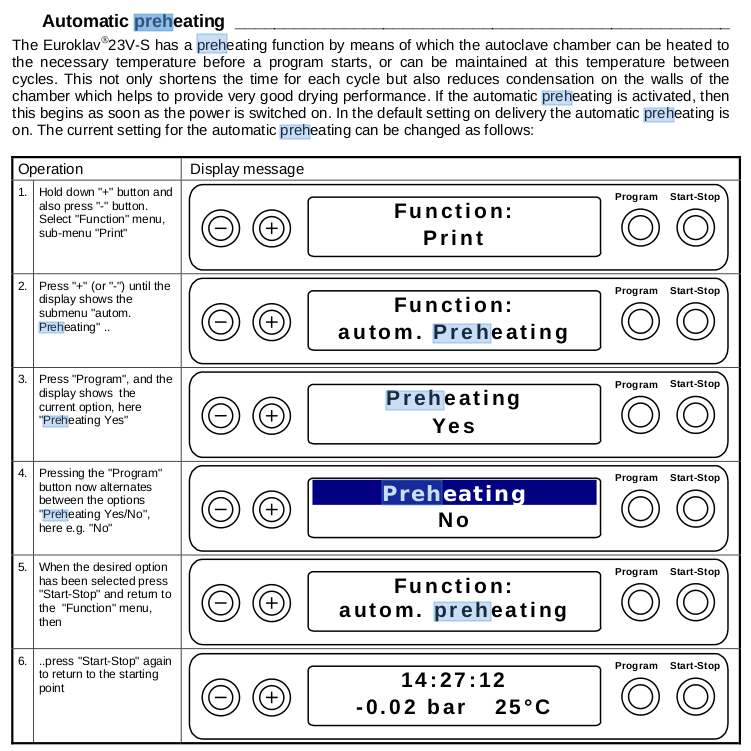

| + | The autoclave should be preheated; | ||

| + | |||

| + | [[File:Screenshot-preheat.png]] | ||

| + | |||

| + | If possible, the media should be split into several autoclaves sessions. The load should be run under the Universal programme | ||

| + | |||

| + | [[File:Screenshot-universal-programme.png]] | ||

| + | |||

Revision as of 18:02, 11 December 2014

Using the Autoclave for Waste Deactivation

| Author: Tolland | Approved by: S. Thompson | SOP No. LBL04006 |

| Signed: | Signed: | Effective from: |

| Date: | Date: | Last edited: |

1. Purpose

This describes the operation of the Melag EuroKlav 29V-S. The autoclave is used for two main procedures with respect to GMO deactivation:

i) sterilization of glassware and equipment for reuse ii) Deactivation of small volumes of GMO exposed media, and GMO exposed waste and equipment. iii)

2. Scope

This should be observed every time the autoclave is used within the LBL BioLab for GMO waste deactivation.

3. Responsibilities

The operator of the autoclave is responsible for their own safety and that of others in the vicinity during its use. The particular risks presented in using this piece of equipment are primarily due to the high temperatures and steam released during evacuation.

Upon removal of items from the autoclave be aware that they will likely still be hot, and care should be taken to check that glass or ceramic items are intact.

4. Materials

The autoclave requires a supply of RO water. If the water supply level falls below a minimum level, the operator will be required to top up the system. The RO water is available from the tank under the counter. The autoclave is filled into the tank from the top of the machine.

The daily test, and waste deactivation runs of the autoclave require autoclave tape. If we are out of autoclave tape, please email the [mailti:hello@biohackspace.org BSO] and report that we are out of stock.

5. Related documents

...

6. Definitions

...

7. Procedures

7.1 Daily Test procedure

Before using the autoclave for GMO deactivation each day, the operator should run a test strip through the autoclave to check that it is working to specification.

The test strip should be stapled into the lab book, with a note indicating the operator and the date/time the test was run, along with any observations.

7.1.1 Unwrapped equipment and glassware with no internal cavities can be sterilized using the Quick Programme (28 psi/134 C/3 mins)

7.1.2 Materials such as a solid and liquid media can be sterilized using the Universal Programme (28 psi/134 C/30 mins)

7.1.3 Large volumes of liquid or solid media should be processed with extra care.

The autoclave should be preheated;

If possible, the media should be split into several autoclaves sessions. The load should be run under the Universal programme

7.2 Deactivation of liquid and solid GMO waste ==

7.2.1 Transport the waste to the autoclave in a non-drip autoclavable tray 7.2.2 Ensure there are no folds or containers which can trap air 7.2.3 Sterilize the load using the Universal-Programme (2.1 bar/134 C/15 mins) 7.2.4 once the programme has run, the waste should be transferred to the chemical kill bin, for final deactivation

8. Resources

- Operating manual: http://www.eickemeyer.nl/images/products/2281/500032_Melag_Euroklav_23VS.pdf