Difference between revisions of "Project:PCB Etch Tank"

m (Reverted edits by Ytogohiga (Talk) to last revision by Danielsikar) |

|||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Idea== | ==Idea== | ||

Revision as of 00:17, 24 November 2010

Idea

A peristaltic pump and possible accoutrements for etching boards. The pump could be used to speed up the etching process by displacing spent etchant from the immediate vicinity of the board. The pump could also be used to bubble air through the Copper Chloride etchant that will soon be in play at the space. The air bubbling is an essential process in regenerating the etchant.

A heat exchanger of some kind could be incorporated to speed up the etching further.

Nice things about peristaltic pumps are:

- easy to make

- easy to clean

- easy to estimate flow rate

- look awesome, especially in clear Acrylic

- work could be repurposed to help with the pizza printer

Existing designs

Possible candidates (lifted from google images):

Clear plastic box adaptation. Not dissimilar to LHS personal boxes.

Another design option, more complex but perhaps doable in acrylic by the laser cutter.

Sketches

Sketches to be inserted here.

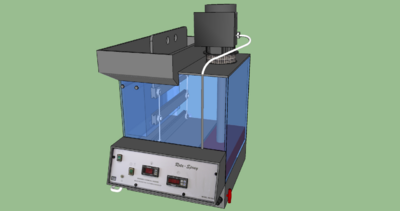

Some ideas from the Google 3D warehouse, both from user davies447.

MEGA Electronics Rota-Spray

PCB Developer Tank