Equipment/Ultimakers: Difference between revisions

mNo edit summary |

mNo edit summary |

||

| Line 1: | Line 1: | ||

There are 2 ultimakers currently on loan from "robots for good" project. They are available for use by members under the acnode system. Given the high cost and delicate nature of this equipment training is available to members who have already been inducted for the lulzbot, or have demonstrable previous experience with Ultimaker 3d print hardware. | There are 2 ultimakers currently on loan from "robots for good" project. They are available for use by members under the acnode system. Given the high cost and delicate nature of this equipment training is available to members who have already been inducted for the lulzbot, or have demonstrable previous experience with Ultimaker 3d print hardware. | ||

{{draft}} | |||

{{EquipmentInfobox | {{EquipmentInfobox | ||

Revision as of 14:29, 23 September 2015

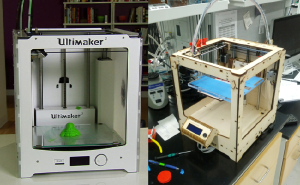

There are 2 ultimakers currently on loan from "robots for good" project. They are available for use by members under the acnode system. Given the high cost and delicate nature of this equipment training is available to members who have already been inducted for the lulzbot, or have demonstrable previous experience with Ultimaker 3d print hardware.

{{#invoke:Template translation|renderTranslatedTemplate|template=Draft/core|1=}}

| Ultimakers 1 & 2 | |

|---|---|

| |

| Sub-category | CNC |

| Status | Good working order |

| Consumables | Printer filament |

| Training requirement | Yes |

| Training link | 3dprinter_training |

| ACnode | yes |

| Owner | Wevolver |

| Origin | Loan |

| Location | Robotics Area, basement |

| Maintainers | Rich, Tolland, Chris?, Ian? |

Description

ACNode is in operation on the Ultimaker-1, the ultimaker-2 is not yet commissioned. In order for your existing training to be approved on ACNode, you must run through a refresher session to ensure you are upto date (ACNode procedures, Octoprint procedures).

If you have been trained previously and need approved on ACNode, contact the maintainers to be added to the acnode.

Specification & documentation

Printing

- Usable Print Area: 200mm x 190mm x 100mm (7.9in x 7.5in x 3.9in)

- Top Print Speed: 200mm/sec (7.9in/sec)

- Print Tolerance: 0.2mm (0.008in) in X and Y axes. Z axis is dependent on layer thickness

- Layer Thickness: 0.15mm (0.0029in) to 0.35mm (0.029in)

- Supported Materials: ABS and PLA plastic filaments

- Usable Filament Sizes: standard 3mm (0.1in)

Consumables

Only filament provided by the maintainers can be used in the Ultimakers. This is to prevent any issues with poor quality filament. If we're running low on filament (or tape), ro recommended alternative providers, let them know (via the mailing list).

Filament options (3.0mm)

- ABS (lego brick plastic - prints at 190-230 DegC, requires heated bed at 100-110 DegC)

- PLA (biodegradable , based on food starch - prints at 185-190 DegC, optional heated bed, not hotter than 60 DegC)

- There are other 'specialist' filament, like wood effect, stone effect, nylon (can be coloured by clothes dye), etc