|

|

| (92 intermediate revisions by 27 users not shown) |

| Line 1: |

Line 1: |

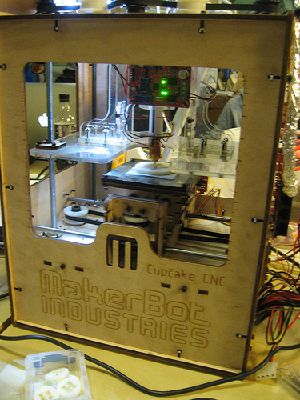

| We have a [http://www.makerbot.com Makerbot Cupcake] (batch 9, #402)! It's cool.

| | {{EquipmentInfobox |

| | |name=Makerbot Cupcake<!-- Name of the item. --> |

| | |image=1.jpg <!-- Image of the item. Leave with placeholder image if none exists. --> |

| | |model=Unknown <!-- Model --> |

| | |category=Equipment <!-- Main category. Please leave alone to keep item in this category --> |

| | |subcat=Scrapped |

| | |status=Scrapped |

| | |consumables=Unknown <!-- Any items used up in normal operation, such as; ink, paper, saw-blades, cutting disks, oil, etc.. --> |

| | |accessories=Unknown <!-- Any items associated with the equipment but not consumable, such as; drill bits, safety gloves, goggles, etc.. --> |

| | |reqtraining=Yes<!-- Is training required to use this equipment? Yes or no. --> |

| | |trainlink=Unknown <!-- If training is required, provide a link to training signup or contact page. Otherwise leave blank. --> |

| | |acnode=<!-- Is the equipment ACnode locked? --> |

| | |owner=Unknown <!-- Provide a link to owners members page if other than LHS --> |

| | |origin=Unknown <!-- If via pledge, please link to the completed pledge page on the wiki --> |

| | |location=<!-- Floor, room/zone and location within that area --> |

| | |maintainers=<!-- NO LINKS PLEASE; it currently breaks the template. If someone is nominated as managing the upkeep of this item, please list them here. --> |

| | |template_ver=1.1 <!-- Please do not change. Used for tracking out-of-date templates --> |

| | }} |

| | [[File:Makerbot-1.jpg|thumb|right]] |

| | [[File:Makerbot-2.jpg|thumb|right]] |

| | == '''<div style="color:red">Please don't touch or fiddle with the Makerbot unless you have been trained. </div>'''== |

| | Training Session 1: Wed 7th September @12:30pm [[User:Samthetechie|Samthetechie]] showed [[User:Billy_Smith|Billy Smith]] |

| | == '''<div style="color:red">DO NOT UPDATE OR EDIT THE FIRMWARE ON THE BOARDS. </div>'''== |

| | Please document the customizations which prevent upgrading the firmware <3 |

| | ==Status== |

| | To try to reduce the stagering amount of damage the Makerbot sustains I've added a key. |

| | [[Equipment/Makerbot_Cupcake/LogBook|operator log]] for more information. |

|

| |

|

| If you haven't used it before, please contact Russ and get him to show you [[makerbot notes|how it works]]

| | ==Model== |

| | We have a [http://www.makerbot.com Makerbot Cupcake] (batch 9, #402)! Now modified to a hipsterbot, extended x, y, z-axis. It's to cool. |

| | ====Specification==== |

|

| |

|

| If you're using the Makerbot and have issues with it, or have to do maintenance/modifications to it, please note them in the logbook below. This lets other users know what the state of the machine is. | | ==Instructions== |

| | If you haven't used it before, please contact Glen or Russ and get him to show you how it works. |

|

| |

|

| Drivers for USB-serial cable: [http://www.ftdichip.com/FTDrivers.htm]

| | If you're using the Makerbot and have issues with it, or have to do maintenance/modifications to it, please note them in the [[Equipment/Makerbot_Cupcake/LogBook|operator log]]. This lets other users know what the state of the machine is, and helps us to avoid repeating errors which lead to breakage. |

|

| |

|

| ==Logbook== | | ====Calibration==== |

| | * [http://wiki.makerbot.com/configuring-skeinforge Makerbot Wiki - Configuring skeinforge] |

|

| |

|

| ===4/08/2010 Operator: samthetechie=== | | ====Connection voodoo==== |

| * checking axis alignment with spirit level.

| | #USB cable maker bot |

| | #USB cable laptop |

| | #Makerbot PSU power on |

| | #Use key to turn power on to system |

| | #~RepRap motherboard power on |

| | #replicatorg |

|

| |

|

| ===31/05/2010 Operator: Jasper=== | | ====Temperature settings==== |

| * didn't actually do anything, just catching up with news

| |

| * glen fixed the print head

| |

| * Solexious fixed the build platform and X axis

| |

| * it's still spooging plastic from the side of the print head

| |

|

| |

|

| ===15/05/2010 Operator: Nandish===

| | ABS melts at 220 °C. |

| *connection/on-off voodoo & preheating with no problem

| | PLA melts at 210 °C |

| *print not started, concerned that metal extruder barrel looks much further out the PTFE Barrel than on the [http://makerblock.com/2010/02/how-to-unclog-your-extruder-barrel-and-nozzle/ assembly instruction]

| |

| **update 17/05/2010: spoke to Russ, this is not normal - replacement part is required

| |

| * [[File:2010-05-16 15.28.31.jpg]]

| |

|

| |

|

| ===03/05/2010 Operator: Jasper===

| | Use ReplicatorG 0025, setting the Machine driver the "Cupcake w/ automated build platform", but the Gcode profile set to "Cupcake w/ heated build platform" (for now, because we don't have a scrubber). |

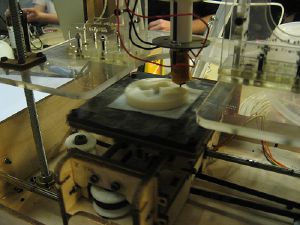

| * printed the bus pirate box for real this time (after a bit more trial and error)

| |

| * the X axis stepper motor was backwards so swapped the connector around, now things won't be mirrored.

| |

| * [[File:Buspiratebox.jpeg]]

| |

|

| |

|

| ===27/04/2010 Operator: Russ (write up by jasper)===

| | The heated build platform should be set to 100-120 °C, and shows up in GCode as the "cooling fan". If controlling the extruder, set it to 255. |

| * [[JasperWallace]] printed a box for a [[BusPirate]], discovering that printed things shrink by 0.5% to 0.75%

| |

|

| |

|

| ===19/04/2010 Operator: Russ===

| | The PTFE Barrel insulates the extruder nozzle |

| * Motherboard + Extruder firmware to v2.0 release 1. HBP now internally powered. | | *PTFE is a thermoplastic polymer. Its melting point is 327 °C, but its properties degrade above 260 °C |

|

| |

|

| ===18/04/2010 Operator: Nandish===

| | The default "3mm" thermistor settings are as follows: |

| * was unable to find SDCard reader - printed via USB | | *Temperature of Raft: 230.0 |

| * multiple failed prints at raft lay down | | *Temperature of Shape First Layer Outline: 215.0 |

| ** unconnected HBP cables lifted plate while it moved warping the raft | | *Temperature of Shape First Layer Within: 215.0 |

| ** abs not adhering to HBP - maybe extrusion temp | | *Temperature of Shape Next Layers: 220.0 |

| ** extruder ploughing up cleanly laid down raft in one corner and printing in mid-air at other

| |

| * resolved raft issues with calibration

| |

| * partially successful print aborted after abs feed caught on speakers

| |

| ** several layers missed, extrusion resumed in mid-air, print aborted

| |

|

| |

|

| ===13/04/2010 Operator: Russ===

| | Yup, that should defo do the trick! |

| * Installed heated build platform v2, externally powered.

| |

|

| |

|

| ===29/03/2010 Operator: Solexious=== | | ==Consumables== |

| * First attempt, extruder was to close to the platform resulting in the abs being 'threaded'. After heating the extruder and manually feeding the abs the makerbot was back in working order.

| |

| * The makerbot successfully printed a single, and a 2X2 grid of Hackspace Coins http://www.thingiverse.com/thing:2113

| |

|

| |

|

| ===29/03/2010 Operator: Russ===

| | I've bought plastic, lots of plastic. |

| * After a couple more crashes, downgraded extruder to 1.5.

| |

|

| |

|

| ===16/03/2010 Operator: Russ===

| | ABS |

| * Ambient temperature is quite a bit warmer now, which probably helps.

| | Black, white, clear, red, yellow, pink green & blue. |

| * Successfully printed a whistle! (the overhang on the top means it's not terribly functional but it finished)

| |

| * Across about 70mins of print time I had two crashes :/

| |

|

| |

|

| ===11/03/2010 Operator: Russ===

| | PLA |

| * Received and fitted new insulator/barrel/nozzle/nichrome. Extruder is working much better now.

| | Clear, green, white and metallic. |

| * Also received 5lbs of PLA. I don't want to use it until we've done the M8 nut mod to the extruder, and we've got a spare insulator retainer. So we're still on ABS.

| |

| * Upgraded motherboard to 1.5, extruder to 1.8 with heated build surface. My ReplicatorG is now 0013.

| |

| * Managed to successfully print an insulator retainer! It's a bit stringy but it's a start.

| |

| * I'm wondering if the thermistor is a way off. Fiddling with the thermistor calibration didn't get very far.

| |

| * I honestly think we're nearly there ;)

| |

|

| |

|

| ===02/03/2010 Operator: Russ===

| | Prices range from 4 to 2.5 pence per gram. |

| * Filament drive pulley replaced. We now have 4 spares.

| | Put money for plastic used in the box marked Glen in the box store room. |

| * Still hitting problems where the filament drive stopped and gouged a hole in the pulley, which seems to indicate barrel undertemperature or blockage.

| |

| * Tried increasing temperature. Increasing extruder temperature above 255 appears to cause the heater to run away. I melted the insulator. Silly me.

| |

| * Ordered new insulator+barrel+nozzle+nichrome.

| |

|

| |

|

| ===11/02/2010 operator; Glen=== | | ==More information== |

| * To print warp free large objects heat the perspex plastic bed to 100'C with the hot air blower then make sure the first two base layers are stuck to the bed by adjusting the Z-axis height. Don't use the electric fan heater as this increases cooling of the plastic. I used the hot air de-soldering blower at 100'C to keep the plastic warm while printing, though I didn't try printing without this.

| | Glen's notes on conversion to RAMPS [http://groups.google.com/group/london-hack-space/browse_thread/thread/4fa699826c0c3506] |

| * The extruder gear wheel has a part missing from it that limits where the plastic feed can rest against the gear teeth. Until the drive gear is replaced the plastic feed can work it's way next to the idler wheel where it will no longer be driven. I tried putting two idler wheels in to stop the feed from having any space to get away from the drive gear, but this didn't work so I went home.

| |

| * Consider selling the printer to some poor fool on eBay, as far as I know it's printed no large objects despite receiving dozens of hours of maintenance and is clearly possessed by angry spirits.

| |

|

| |

|

| ===09/02/2010 Operator: Russ=== | | ====Software==== |

| * Extruder with 2 idler wheels doesn't appear to work at all. | | * [http://www.ftdichip.com/FTDrivers.htm Drivers] for USB-serial cable (also [http://www.ftdichip.com/Drivers/VCP.htm here]). |

| * Reassembled the extruder with one idler wheel, moving the drive wheel up the shaft a little. | | * skeinforge |

| * This works, but the extruder stalls after a random amount of time! WTF. We need a new drive wheel. | | * http://replicat.org/ |

|

| |

|

| ===08/02/2010 Operator: Glen=== | | ====Communities==== |

| * Can printed half a large object with no warping by melting the raft to the print surface. | | *[http://www.fabathome.org/wiki/index.php?title=Main_Page Fab @ Home] |

| * Print-head failed push plastic feed into nozzle

| | *http://fabacademy.org |

| * Dismantled the print-head and found the gear that drives the plastic feed stock had broken in two and the two parts had ground against each other to produce many tiny metal shards.

| | *http://www.thingiverse.com/ |

| * After cleaning the print-head the plastic would not come through unless pushed by hand.

| |

|

| |

| ===06/02/2010 Operator: Russ===

| |

| * Downgraded both motherboard and extruder to 1.5 firmware. | |

| * Printing off SD card, no crashes observed. | |

| * Managed to get about 80% of a shot glass printed. Glitches caused by contraction were an issue, and eventually it got knocked off by the print head.

| |

| * I'm fairly sure the hardware is working fine. Problems I'm now seeing are caused by either ambient temperature/airflow or skeinforge settings.

| |

|

| |

|

| ===04/02/2010 Operator: Russ=== | | ====Instructions==== |

| * Walked in, started it up, extruder works fine. | | *[http://wiki.makerbot.com/how-to-print How To Print: an overview of turning a thought into an object] |

| * Extruder idler pulley needed re-adjusting twice. ('''Note:''' that the thin silvery metal bar in the Makerbot toolkit is designed to be used as a spacer for this.) Should be done up nice and tight now though.

| |

| * Continual tweaking of z-stage stepper strength, now at about 75%

| |

| * Accidental Z-stage/build platform collision required re-levelling of Z-stage (seems the best way to do this is by releasing one of the Z idler pulleys and twisting the studding, instead of fiddling with the nuts). Seems pretty smooth now.

| |

| * X belt tension was too low, there was a lot of slop. It's pretty tricky to get it tight enough.

| |

| * Lots of bolts on the XY stage were loose! This makes a horrendous racket when it's actually printing at full speed... Tightened them up

| |

| * Packed both X runner bars with hot glue, they were also moving about and making a racket.

| |

| * I managed to make it print 1/3rd of a shot glass, then it crashed. (About 60,000 gcode commands/30mins in.) Need to know what firmware to put on it to stop the crashing.

| |

|

| |

|

| Following changes over skeinforge 0006 defaults are active (on my laptop):

| | [[Category:Equipment]] |

| | |

| Feedrate: 27.0 mm/s

| |

| Base Layer Thickness over Layer Thickness: 1.5

| |

| Interface Layer Thickness over Layer Thickness: 0.8

| |

| Makerbot Cupcake |

|---|

|

| Model |

Unknown |

|---|

| Sub-category |

Scrapped |

|---|

| Status |

Scrapped |

|---|

| Last updated |

1 June 2013 12:03:42 |

|---|

| Consumables |

Unknown |

|---|

| Accessories |

Unknown |

|---|

| Training requirement |

Yes |

|---|

| Training link |

Unknown |

|---|

| Owner |

Unknown |

|---|

| Origin |

Unknown |

|---|

Please don't touch or fiddle with the Makerbot unless you have been trained.

Training Session 1: Wed 7th September @12:30pm Samthetechie showed Billy Smith

DO NOT UPDATE OR EDIT THE FIRMWARE ON THE BOARDS.

Please document the customizations which prevent upgrading the firmware <3

Status

To try to reduce the stagering amount of damage the Makerbot sustains I've added a key.

operator log for more information.

Model

We have a Makerbot Cupcake (batch 9, #402)! Now modified to a hipsterbot, extended x, y, z-axis. It's to cool.

Specification

Instructions

If you haven't used it before, please contact Glen or Russ and get him to show you how it works.

If you're using the Makerbot and have issues with it, or have to do maintenance/modifications to it, please note them in the operator log. This lets other users know what the state of the machine is, and helps us to avoid repeating errors which lead to breakage.

Calibration

Connection voodoo

- USB cable maker bot

- USB cable laptop

- Makerbot PSU power on

- Use key to turn power on to system

- ~RepRap motherboard power on

- replicatorg

Temperature settings

ABS melts at 220 °C.

PLA melts at 210 °C

Use ReplicatorG 0025, setting the Machine driver the "Cupcake w/ automated build platform", but the Gcode profile set to "Cupcake w/ heated build platform" (for now, because we don't have a scrubber).

The heated build platform should be set to 100-120 °C, and shows up in GCode as the "cooling fan". If controlling the extruder, set it to 255.

The PTFE Barrel insulates the extruder nozzle

- PTFE is a thermoplastic polymer. Its melting point is 327 °C, but its properties degrade above 260 °C

The default "3mm" thermistor settings are as follows:

- Temperature of Raft: 230.0

- Temperature of Shape First Layer Outline: 215.0

- Temperature of Shape First Layer Within: 215.0

- Temperature of Shape Next Layers: 220.0

Yup, that should defo do the trick!

Consumables

I've bought plastic, lots of plastic.

ABS

Black, white, clear, red, yellow, pink green & blue.

PLA

Clear, green, white and metallic.

Prices range from 4 to 2.5 pence per gram.

Put money for plastic used in the box marked Glen in the box store room.

More information

Glen's notes on conversion to RAMPS [1]

Software

Communities

Instructions