Equipment/LatheMillCombo: Difference between revisions

(→Tools) |

No edit summary |

||

| (8 intermediate revisions by 3 users not shown) | |||

| Line 4: | Line 4: | ||

|model=[http://www.chesteruk.net/products/detail/12 Chester Centurion 3-in-1 500mm] <!-- Model --> | |model=[http://www.chesteruk.net/products/detail/12 Chester Centurion 3-in-1 500mm] <!-- Model --> | ||

|category=Equipment <!-- Main category. Please leave alone to keep item in this category --> | |category=Equipment <!-- Main category. Please leave alone to keep item in this category --> | ||

|subcat= | |subcat=defunct <!-- Sub-category if one exists. Please check main listing to see other categories contained within the main one --> | ||

|status= | |status=Retired | ||

|consumables=Unknown <!-- Any items used up in normal operation, such as; ink, paper, saw-blades, cutting disks, oil, etc.. --> | |consumables=Unknown <!-- Any items used up in normal operation, such as; ink, paper, saw-blades, cutting disks, oil, etc.. --> | ||

|accessories= | |accessories=125mm 3-Jaw Chuck, 1-13mm Drill Chuck & Arbor, MT4 & MT3 Steel entres, Lathe Tool Set, Milling Drawbar, 4-Way Indexing Toolpost, Combined Vice/Compound Slide, Lathe & Drill Chuck Guards | ||

|reqtraining=Yes <!-- Is training required to use this equipment? Yes or no. --> | |reqtraining=Yes <!-- Is training required to use this equipment? Yes or no. --> | ||

|trainlink=[[ | |trainlink=[[Lathe_Training]] <!-- If training is required, provide a link to training signup or contact page. Otherwise leave blank. --> | ||

|acnode=Yes <!-- Is the equipment ACnode locked? --> | |acnode=Yes <!-- Is the equipment ACnode locked? --> | ||

|owner=LHS <!-- Provide a link to owners members page if other than LHS --> | |owner=LHS <!-- Provide a link to owners members page if other than LHS --> | ||

|origin=Pledged March 2011 <!-- If via pledge, please link to the completed pledge page on the wiki --> | |origin=Pledged March 2011 <!-- If via pledge, please link to the completed pledge page on the wiki --> | ||

|location= | |location=Gone <!-- Floor, room/zone and location within that area --> | ||

|maintainers= | |maintainers=Liam, Ian, Dean, Russ <!-- If an individual is nominated as managing the upkeep of this item, please list them here. --> | ||

|template_ver=1.1 <!-- Please do not change. Used for tracking out-of-date templates --> | |template_ver=1.1 <!-- Please do not change. Used for tracking out-of-date templates --> | ||

}} | }} | ||

'''<div style="color:red">Please don't use the 3 in 1 Lathe unless you have been [[Lathe_training|trained]]. </div>''' | '''<div style="color:red">Please don't use the 3 in 1 Lathe unless you have been [[Lathe_training|trained]]. </div>''' | ||

| Line 26: | Line 24: | ||

==Safety Information== | ==Safety Information== | ||

'''This is a dangerous machine''', and is perfectly capable of causing serious injury. For this reason, you ''must'' be trained to use it. It's fitted with a key-switch emergency stop so that only keyholders can switch it on. | '''This is a dangerous machine''', and is perfectly capable of causing serious injury. For this reason, you ''must'' be trained to use it. It's fitted with a and [[Project:ACNode|ACNode]] and a key-switch emergency stop so that only keyholders can switch it on. | ||

It's worth reading around the subject before you try to start on the actual machine - it's easy to teach some simple basic operation, but much harder to teach all the things you SHOULDN'T do. You've got to get a real sense of your limitations, and '''always''' research any new operation to make sure you're doing it safely. There are pointers to educational materials in the [[Library#Machining|Library]] | It's worth reading around the subject before you try to start on the actual machine - it's easy to teach some simple basic operation, but much harder to teach all the things you SHOULDN'T do. You've got to get a real sense of your limitations, and '''always''' research any new operation to make sure you're doing it safely. There are pointers to educational materials in the [[Library#Machining|Library]] | ||

| Line 49: | Line 47: | ||

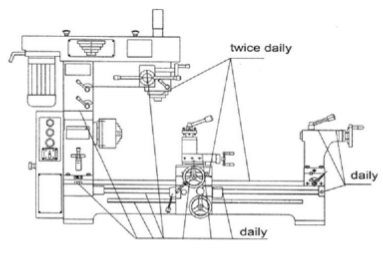

[[File:Centurion_oiling.png|thumb|500px|right|Oiling schedule from manual]] | [[File:Centurion_oiling.png|thumb|500px|right|Oiling schedule from manual]] | ||

'''Oiling is critical to keeping the 3-in-1 in a good condition.''' The machine must be oiled before and after every use. The slideways should be oiled with slideway oil, and all other parts should be oiled with general-purpose machine oil. See the full manual for further details: [[File:Centurion_Instruction_Manual.pdf]] | '''Oiling is critical to keeping the 3-in-1 in a good condition.''' The machine must be oiled before and after every use. The slideways should be oiled with slideway oil, and all other parts should be oiled with general-purpose machine oil. See the full manual for further details: [[File:Centurion_Instruction_Manual.pdf]] | ||

=== Updates === | |||

* 10-JUL-2014 (James): I spent a fair chunk of time making a new micro switch aluminium shaft & chuck guard for the 3 in 1. Now it lets you open the chuck jaws to their full potential with ample clearance from the edge of the Perspex. I designed it so it stays horizontal relative to the chuck and will not operate if the chuck key is located in the chuck. | |||

===Tools=== | ===Tools=== | ||

| Line 65: | Line 67: | ||

If you would like to help there is an [[Pledges/Lathe_Milling_Machine_Combo_Tools | active pledge]] to buy more tools for this machine. | If you would like to help there is an [[Pledges/Lathe_Milling_Machine_Combo_Tools | active pledge]] to buy more tools for this machine. | ||

It | It is recommended that you supply your own cutting tools, e.g. [http://www.glanze.co.uk/acatalog/Single_Turning_Tools.html 12mm shank tools]. It's generally not recommended to grind your own cutting tools unless you really know what you're doing (and have the time!) | ||

==Projects== | ==Projects== | ||

| Line 76: | Line 78: | ||

The current maintainers on the 3-in-1 are: | The current maintainers on the 3-in-1 are: | ||

* Liam Lynch | |||

* Ian H, | * Ian H, | ||

* Dean Forbes | |||

* Adrian | * Adrian | ||

* Russ | * Russ | ||

Please speak to one of these people if you encounter any problems with the lathe. '''Maintainers are NOT cleaners''' however so don't expect them to clean up for you! If you can't find them immediately, make sure you email the list. | Please speak to one of these people if you encounter any problems with the lathe. '''Maintainers are NOT cleaners''' however so don't expect them to clean up for you! If you can't find them immediately, make sure you email the list. | ||

Latest revision as of 12:08, 21 January 2019

| 3-in-1 Lathe | |

|---|---|

| |

| Model | Chester Centurion 3-in-1 500mm |

| Sub-category | defunct |

| Status | Retired |

| Consumables | Unknown |

| Accessories | 125mm 3-Jaw Chuck, 1-13mm Drill Chuck & Arbor, MT4 & MT3 Steel entres, Lathe Tool Set, Milling Drawbar, 4-Way Indexing Toolpost, Combined Vice/Compound Slide, Lathe & Drill Chuck Guards |

| Training requirement | Yes |

| Training link | Lathe_Training |

| ACnode | Yes |

| Owner | LHS |

| Origin | Pledged March 2011 |

| Location | Gone |

| Maintainers | Liam, Ian, Dean, Russ |

London Hackspace has a Chester Centurion 3-in-1 500mm lathe/mill/drill. This is a useful tool for tasks which are too large for our mini mill & lathe.

Safety Information

This is a dangerous machine, and is perfectly capable of causing serious injury. For this reason, you must be trained to use it. It's fitted with a and ACNode and a key-switch emergency stop so that only keyholders can switch it on.

It's worth reading around the subject before you try to start on the actual machine - it's easy to teach some simple basic operation, but much harder to teach all the things you SHOULDN'T do. You've got to get a real sense of your limitations, and always research any new operation to make sure you're doing it safely. There are pointers to educational materials in the Library

Training

For full information and to sign up to training sessions, see the Lathe Training page

More information on Lathe Training. Add tips to the Poster.

MIT have 3 videos about working with a lathe. You will still need in-person training, but they are full of good tips and will help everything go smoothly.

- Lathe 1: Lathe basics; turning and facing; cutting off a part

- Lathe 2: Tapping; boring; knurling; cutting tapers; turning shafts with a live centre; single point thread turning

- Lathe 3: Chucking large items; using lathe arbours; turning between centres; working with irregular shapes & thin materials.

Using the 3-in-1 Lathe

The Logbook is used to record any changes, problems or concerns about the machine.

Oiling is critical to keeping the 3-in-1 in a good condition. The machine must be oiled before and after every use. The slideways should be oiled with slideway oil, and all other parts should be oiled with general-purpose machine oil. See the full manual for further details: File:Centurion Instruction Manual.pdf

Updates

- 10-JUL-2014 (James): I spent a fair chunk of time making a new micro switch aluminium shaft & chuck guard for the 3 in 1. Now it lets you open the chuck jaws to their full potential with ample clearance from the edge of the Perspex. I designed it so it stays horizontal relative to the chuck and will not operate if the chuck key is located in the chuck.

Tools

A basic set of tooling is already available:

- 125mm 3-Jaw Chuck

- 1-13mm Drill Chuck & Arbor

- MT4 & MT3 Steel centres

- Lathe Tool Set

- Milling Drawbar

- 4-Way Indexing Toolpost

- Combined Vice/Compound Slide

- Lathe & Drill Chuck Guards

If you would like to help there is an active pledge to buy more tools for this machine.

It is recommended that you supply your own cutting tools, e.g. 12mm shank tools. It's generally not recommended to grind your own cutting tools unless you really know what you're doing (and have the time!)

Projects

Please list here your projects

- Metal Syringe Dean

Maintenance

The current maintainers on the 3-in-1 are:

- Liam Lynch

- Ian H,

- Dean Forbes

- Adrian

- Russ

Please speak to one of these people if you encounter any problems with the lathe. Maintainers are NOT cleaners however so don't expect them to clean up for you! If you can't find them immediately, make sure you email the list.

More Information

Add your links here with a small description.