Bandsaw - Miniature (Lumberjack BS200): Difference between revisions

No edit summary |

No edit summary |

||

| (6 intermediate revisions by 2 users not shown) | |||

| Line 21: | Line 21: | ||

'''Replacement blades''' | '''Replacement blades''' | ||

1400mm (55.1/8") long | |||

[[File: | Standard spec is 6mm (1/4") wide and 6TPI | ||

Plastic inlet can be 3D printed. The files for printing are [https://github.com/riskaone/lhs/tree/main/Bandsaw200 here] | |||

[[File:Bandsaw200 Plastic Inlet 2.jpg|frameless]] | |||

{{:Risk Assessment/ Bandsaws}} | |||

Latest revision as of 08:38, 15 November 2024

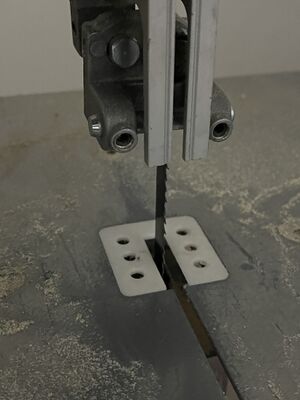

A small bandsaw for making straight or curved cuts in wood or plastic materials

This is a small bandsaw fitted with a thin 1/4" blade. It is a good option for curve cutting in thicker material than the scroll saw can handle, but where the curves required are tighter than the large bandsaw can handle Also useful for straight cuts in thin or delicate material where the larger machine would be unsuitable

It is not well suited to cutting thick material, and please ask for training on the large bandsaw if you need to process thicker stock

Replacement blades

1400mm (55.1/8") long

Standard spec is 6mm (1/4") wide and 6TPI

Plastic inlet can be 3D printed. The files for printing are here

Risk Assessment - Bandsaws

This risk assessment is intended to provide guidance on the risk associated with the above equipment and activities in normal use. Please also check general risk assessments for the space as a whole. Any discrepancies, errors or concerns should be raised with the document maintainers or trustees - do not edit this assessment directly. For responsible persons and last update, see 'version log' of the assessment page.

Activity

Cutting material with a bandsaw

Signage

Understanding Risk Rating

LOW - Ensure current control measures are in place and continue with activity

MED - Control measures may be adequate, co-supervision is recommended

HIGH - Do not undertake activity without further consultation with area specialists

Risk Assessment

| Identify Hazards | Who May be Harmed and How | Severity | Control Measures | Likelihood | Risk Rating |

|---|---|---|---|---|---|

| Incompetent user | User, Bystander | HIGH | Users must not use tools that they are not competent to use. Members must challenge use that they believe is dangerous. Users must read the user manual where applicable. Users must read the risk assessment before using a tool. Users will be advised during induction which tools they will need supervision or n induction to use. Only authorised members will complete maintenance and calibration tasks. | LOW | MED |

| Contact with blade | User | HIGH | Do not put hands into exclusion zone (within 10cm of blade). Use a push stick and the fence provided when making straight cuts. Do not move hands past the blade Saw should be turned off immediately after use Saw blade should stop within 10 seconds of being turned off. | LOW | MED |

| Drawing in (being pulled into the saw) | User | HIGH | User of the saw should not wear gloves, ties, scarves, or other long flowy clothing that could get pulled into the blade. Do not move hands past the blade | LOW | MED |

| Dust (inhalation, fire, explosion) | User, Bystander | MED | Stationary tools should be used with the workshop dust extractor. Maintenance must include the cleaning of dust from within the saw housing where accessible. A respirator or mask should be used whilst operating this tool for prolonged periods. | LOW | LOW |

| Blade snatching or jamming | User, Bystander | HIGH | Only cut wood and plastic on the band saw Do not attempt to make sharp angle cuts in one attempt Ensure a visual inspection of the band saw is undertaken before every use for physical obstructions | LOW | MED |

| Noise | User, Bystander | MED | Ear protection is advised. | LOW | LOW |

| Flying splinters | User, Bystander | HIGH | Eye protection must be worn In the workshop | LOW | MED |