Table Saw (Dewalt DW745): Difference between revisions

(new photo) |

(do not defeat or remove safety equipment.) |

||

| Line 20: | Line 20: | ||

|category=Equipment | |category=Equipment | ||

|subcat=Woodworking | |subcat=Woodworking | ||

|status=Faulty motor, bad rip fence, missing guard, missing riving knife | |status=Faulty motor, bad rip fence, missing guard, missing riving knife, riving knife bracket cannibalised for parts for the new saw. | ||

|accessories=Guard, push-stick, gantry | |accessories=Guard, push-stick, gantry | ||

|reqtraining=yes | |reqtraining=yes | ||

| Line 29: | Line 29: | ||

|maintainers=Phil (cepmender) | |maintainers=Phil (cepmender) | ||

}} | }} | ||

New blade added | New blade added January 2017. | ||

Do not use this without training. | * Do not use this without training. | ||

* If you need to remove the safety guard, '''replace after use'''. Do not lose the butterfly nut. | |||

* If you need to remove the riving knife (for instance, to use a sledge), you should not need to dismantle the device, Unplug, remove throat plate, push the sprung-loaded bolt on the riving knife bracket to release. '''Replace after use.''' | |||

* If you need to remove the mitre gauge, '''put it back in the groove afterwards'''. Do not over-tighten the thumb nut. | |||

* Do not attempt to move the rip fence or saw angle without loosening the locking levers (This breaks the rail gearing, and is stupid). | |||

* Lock all locking levers before cutting. | |||

* Do not remove the laminated instructions from the vicinity of the table saw. Knowledge is power. Knowledge of power tools prevents maiming and death. | |||

* Always leave the saw with all safety features in place. The next user could be a novice. | |||

Mailing list conversations on it: [https://groups.google.com/forum/#!/london-hack-space/f4zdwiVH-uA/1YPXtSxnVFMJ] [https://groups.google.com/forum/#!london-hack-space/eUo1V63h08Q/l0GzvKSlQzgJ] [https://groups.google.com/forum/#!topic/london-hack-space/KpV7wd6y8Dk] [https://groups.google.com/forum/#!topic/london-hack-space/gs2TjB0ptZo] | Mailing list conversations on it: [https://groups.google.com/forum/#!/london-hack-space/f4zdwiVH-uA/1YPXtSxnVFMJ] [https://groups.google.com/forum/#!london-hack-space/eUo1V63h08Q/l0GzvKSlQzgJ] [https://groups.google.com/forum/#!topic/london-hack-space/KpV7wd6y8Dk] [https://groups.google.com/forum/#!topic/london-hack-space/gs2TjB0ptZo] | ||

| Line 41: | Line 48: | ||

---- | ---- | ||

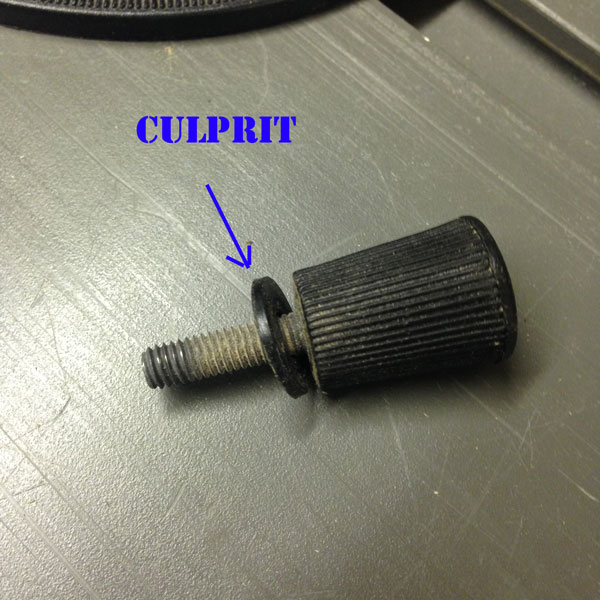

I noticed the | I noticed the mitre gauge is not moving smoothly across the top surface at all. This forces the user to use excessive force when pushing a piece of wood at an angle towards the blade. This can be very dangerous and increases the risk of somebody accidentally getting his hand hit the blade. I definitely would not want to be using this machine like that! It also prevents you from making a clean, smooth cut through the wood. So, after trying to figure out why the mitre gauge gets stuck halfway the table top when sliding it I came to the conclusion that the little plastic washer underneath the tightener knob doesn't belong there. I've moved it from underneath the knob to underneath the gauge (please see pictures). That seems to have solved the problem. Mitre gauge now running smoothly across the full length of the guide rail. I suggest we keep the washer where it is now. Maybe it saved somebody's hand or fingers already, who knows. | ||

Thanks to this [http://airtoolguy.com/best-table-saw-reviews/ table saw] guide to help me pinpoint the problem. | Thanks to this [http://airtoolguy.com/best-table-saw-reviews/ table saw] guide to help me pinpoint the problem. | ||

Revision as of 11:57, 5 January 2017

New blade added January 2017.

- Do not use this without training.

- If you need to remove the safety guard, replace after use. Do not lose the butterfly nut.

- If you need to remove the riving knife (for instance, to use a sledge), you should not need to dismantle the device, Unplug, remove throat plate, push the sprung-loaded bolt on the riving knife bracket to release. Replace after use.

- If you need to remove the mitre gauge, put it back in the groove afterwards. Do not over-tighten the thumb nut.

- Do not attempt to move the rip fence or saw angle without loosening the locking levers (This breaks the rail gearing, and is stupid).

- Lock all locking levers before cutting.

- Do not remove the laminated instructions from the vicinity of the table saw. Knowledge is power. Knowledge of power tools prevents maiming and death.

- Always leave the saw with all safety features in place. The next user could be a novice.

Mailing list conversations on it: [1] [2] [3] [4] Donated to hackspace.

How a misplaced washer increases the risk of somebody cutting their fingers off (or worse!)

I noticed the mitre gauge is not moving smoothly across the top surface at all. This forces the user to use excessive force when pushing a piece of wood at an angle towards the blade. This can be very dangerous and increases the risk of somebody accidentally getting his hand hit the blade. I definitely would not want to be using this machine like that! It also prevents you from making a clean, smooth cut through the wood. So, after trying to figure out why the mitre gauge gets stuck halfway the table top when sliding it I came to the conclusion that the little plastic washer underneath the tightener knob doesn't belong there. I've moved it from underneath the knob to underneath the gauge (please see pictures). That seems to have solved the problem. Mitre gauge now running smoothly across the full length of the guide rail. I suggest we keep the washer where it is now. Maybe it saved somebody's hand or fingers already, who knows.

Thanks to this table saw guide to help me pinpoint the problem.

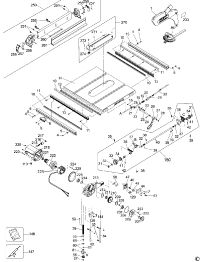

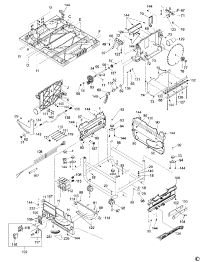

Manual available at

http://service.dewalt.co.uk/Products/ProductDetail.aspx?ProductID=9347&BOMRegionID=1

Parts Diagrams