Equipment/Staubli: Difference between revisions

From London Hackspace Wiki

Deanforbes (talk | contribs) No edit summary |

Deanforbes (talk | contribs) No edit summary |

||

| Line 96: | Line 96: | ||

[https://docs.google.com/spreadsheet/ccc?key=0AqarnpYKaciedFZjTUg4eWd6TDJhblh1UU9xUjFZSWc&usp=sharing Padski's Cable Schematic] | [https://docs.google.com/spreadsheet/ccc?key=0AqarnpYKaciedFZjTUg4eWd6TDJhblh1UU9xUjFZSWc&usp=sharing Padski's Cable Schematic] | ||

[[Equipment/Staubli/Controller|The Linux setup on the ARM controller board]] | [[Equipment/Staubli/Controller|The Linux setup on the ARM controller board]] | ||

Revision as of 15:40, 10 March 2018

Kindly donated to us by Queen Mary's University, was missing arm and power cables.

The arm is being worked on by the robotics group (more help welcome)

Applications

- Potential applications

- 3D scanning possibly using KinectFusion

- Persistence of vision experiments (such as this display at Trafalgar Square)

- High speed orbital photography

- CNC (Dependent on the G-code interpreter)

- PCB manufacture:

- Milling

- Drilling

- solder paste application for SMT components

- pick and place for SMT components

- Currently worked on

Status

The arm is currently a work in progress. It is driven by an open source controller due to failure of the original controller however we still need to complete the kinematics for it

Specs

- Robot arm

- Type: RX60L

- Reference/machine number: 597411 - 01

- Fabrication Le F - 12 - 1997

- Masse kg 42Kg

- Controller

- Type CS7 - M RX60

- 3 x 400V - 50/60 Hz

- 4000VA

- Masse kg 80Kg

- STMBL

- Type 4.1

- The STMBL along with Messa cards driven by linuscnc have been used to control the arm, massive support has been received from the open source community (STMBL and LinuxCNC) as well as Messa who did a custom firmware reactivity for us while we were having a hack weekend - great international and multidisciplinary team work.

We have movement https://flic.kr/p/21GzpWj

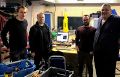

Some photos/videos of the beast

There is a 19 way cable running inside the arm, to allow external signals to be routed to the end effector. This uses a 19 way plug on the wrist joint and base called a Binder Connector.

There is a 50 way connector (J11) at the back of the controller containing the digital IO lines.

TODO

- Necessary

Build a smooth solid table surrounding the arm.

- Nice to have

Document .

Docs/Links

Robot startup/shutdown procedure