Denford CNC 2600: Difference between revisions

| Line 49: | Line 49: | ||

*VR CNC Control Software v5 Training Guide [[File:VR_Milling_5.pdf]] | *VR CNC Control Software v5 Training Guide [[File:VR_Milling_5.pdf]] | ||

*Spindle VFD [[File:Baldor-VS1ST-Micro-Series-Manual.pdf]] | *Spindle VFD [[File:Baldor-VS1ST-Micro-Series-Manual.pdf]] | ||

*Stepper drive [[File:MSD556-V2.0 stepper-drive-datasheet-v3.0.pdf]] | |||

===== MESA 7i76 ===== | ===== MESA 7i76 ===== | ||

Revision as of 23:01, 14 March 2022

| Denford CNC | |

|---|---|

| |

| Model | 2600 pro |

| Sub-category | CNC |

| Status | View tool status |

| Last updated | 19 August 2024 07:32:52 |

| Training requirement | yes |

| Training link | cnc_denford_2600_training |

| ACnode | not yet |

| Owner | LHS |

| Origin | Donation |

| Location | Ground Floor, Woodshop |

| Maintainers | Kunal Claude Steve Dean |

Next steps

- Install MESA

- Configure Linuxcnc

- dust extraction

There is a hole at the top rear left of the cabinet which may be used for dust extraction - either a separate unit or a connection to the shop extractor. However, the cutting dust tends to lie around the cutter so some means to move it to the extraction is required. Possibilities are throwing it into the air and then extracting the air, or sucking directly at the cutting tip. There is a small air pump in the cabinet whose output is taken to a connector under the gantry parking position. This may be used to disturb the air near the cutter, and a flexible hose to the extraction used to remove it. The hoses needed may get in the way : this requires some experiment. A dust shoe may be helpful but will hide the cutting point from view.

- Prepare Inductions

- AC Node

Collets

- We are using ER 20 collets

- You will need to provide your own tooling

- Use of collets ER Collet Essentials. https://www.youtube.com/watch?v=WKikm6cQKh0

Training and induction s

TBD

Materials

- This is in the woodshop and to be used on non metal materials only.

- No liquid or mist coolant is to be used in the machine at all.

Schematics

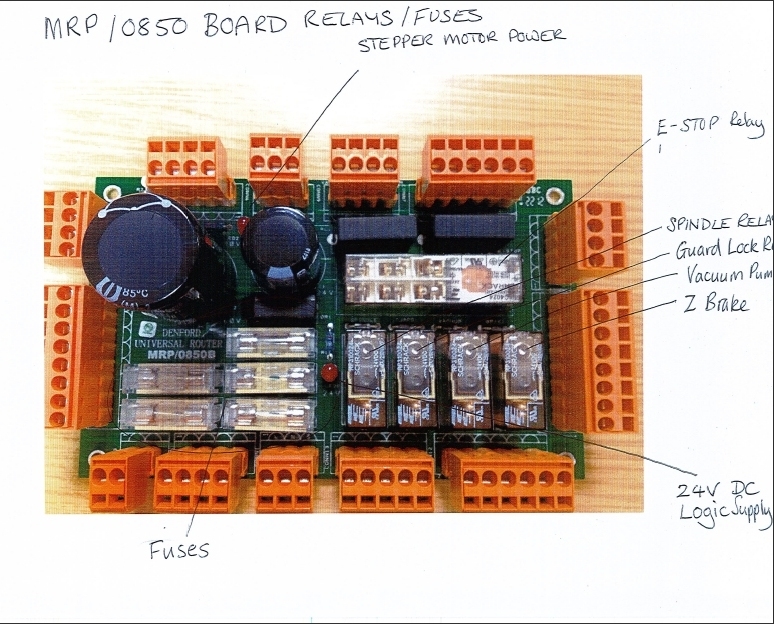

- File:MRP-0850 ESTOP relay contacts.pdf

- Schematic design B (Note we have version A so there maybe some differences) File:Schematic Design MRP-0850B.pdf

- Cabinet Wiring

Manuals

- User Manual File:Router 2600 Pro Operator Manual.pdf

- VR CNC Control Software v5 Training Guide File:VR Milling 5.pdf

- Spindle VFD File:Baldor-VS1ST-Micro-Series-Manual.pdf

- Stepper drive File:MSD556-V2.0 stepper-drive-datasheet-v3.0.pdf

MESA 7i76

- 7i76e Manual File:7i76eman.pdf

- 7i76e Connection Guide File:7i76 Con Guide.pdf

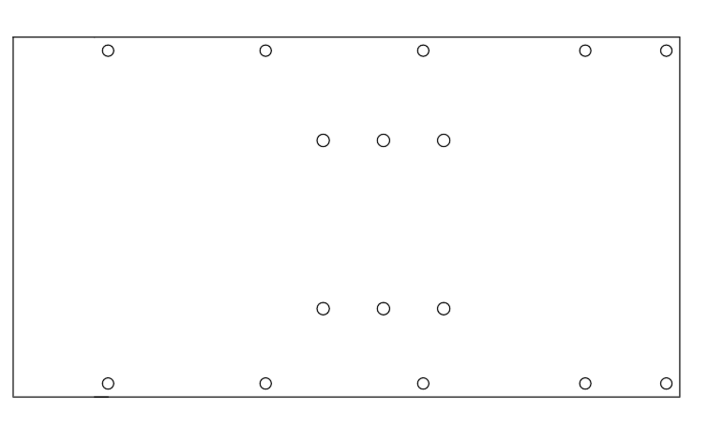

- 7i76e Mounting Base File:7i76E mounting base 2.pdf

Plate 262x140 Cabinet mounting holes for this base are 132x212, 20 from LHS and 30 from RHS Mesa board to be at LHS

Linuxcnc

TBD - GITHUB Repository