Pledge: Robot arm table: Difference between revisions

mNo edit summary |

|||

| Line 39: | Line 39: | ||

* £20 - [[User:JonRussell|Jon]] | * £20 - [[User:JonRussell|Jon]] | ||

* £10 - [[User:increpare|Stephen L]] | * £10 - [[User:increpare|Stephen L]] | ||

* £10 - [[User:bmsleight|bmsleight]] | |||

Running total: '''£90''' | Running total: '''£90''' | ||

Revision as of 20:32, 9 May 2014

This pledge is for a table for our Staubli industrial robot arm and the immediate area around it.

Pledge leader: mentar

News

- Pledge started

What?

On 7th June 2013 we were donated an industrial grade Staubli robot arm. Since then we reverse engineered it, pledged for a cable which we made at less than a 10th of the cost and on 29th of April, after a lot of work, we managed to get our first successful cut (video). We now need a table to create a safe working area to allow those who want to use for arm for whatever purpose, be it CNCing, 3D printing, 3d scanning or innovative (and safe!) uses.

Moar Details

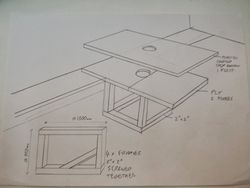

We plan to

- build a wooden frame, out of 2"x2"

- screw a plywood table top on top of it, made from two sheets of ply butted together

- glue (or screw from below) a single 2mx2m sheet of plastic coated chip board on top, to form the final table surface. The ply provides stability and strength. The plastic coated chipboard provides a flat, level surface to work on.

- add a kitchen worktop on the perimeter of the room for other CNC machines, desktops and tools. We plan to use some of the numerous table legs that we have lying around in the corner.

The wood frames are cheap and easy to make. We could use metal, but that is more difficult to cut and requires welding.

Rough costs :

- 2x2 plastic coated chipboard = £65

- 2 x sheets 18mm ply = £24 (£12ea)

- 8 x 2.4m 44x44 timber = £35

- Bag of 3.5" wood screws = £10 (pk of 100)

- 2 x 3m kitchen worktop surfaces = £100 (£50ea)

Total estimate = £235

Pledges

Running total: £90

Approximate target: £235