Difference between revisions of "Equipment/HPC LS3060 Laser Cutter/LogBook"

| Line 1: | Line 1: | ||

__NOTOC__ | __NOTOC__ | ||

==Logbook== | ==Logbook== | ||

| + | |||

| + | === 10/9/2011 note by mars === | ||

| + | Tried the same cut with reduced power and changed the engraving 'gap' setting. Scan gap was set to 0.05 which causes quite extreme striation. With speed=400 and scan gap=0.01 things didn't go well - the engraving didn't seem to progress horizontally at all and the head started moving off the bed. Not sure if this was caused by belt slippage, but I had to stop and reset the head position. | ||

| + | To engrave on perspex, seems to work well when halving power, e.g. power=10 speed=200 gap=0.025. Makes a nice, solid pattern. I tried with the recommended power=20, which went well deep and scorched, actually charred, the material. Not seen that before. | ||

| + | Cut 4mm perspex at power 60, speed 4. Might be possible to turn power down even more. | ||

| + | In short, to cut or engrave reduce the power by 1/2! | ||

===8/9/2011 by asc === | ===8/9/2011 by asc === | ||

Revision as of 00:42, 11 September 2011

Logbook

10/9/2011 note by mars

Tried the same cut with reduced power and changed the engraving 'gap' setting. Scan gap was set to 0.05 which causes quite extreme striation. With speed=400 and scan gap=0.01 things didn't go well - the engraving didn't seem to progress horizontally at all and the head started moving off the bed. Not sure if this was caused by belt slippage, but I had to stop and reset the head position. To engrave on perspex, seems to work well when halving power, e.g. power=10 speed=200 gap=0.025. Makes a nice, solid pattern. I tried with the recommended power=20, which went well deep and scorched, actually charred, the material. Not seen that before. Cut 4mm perspex at power 60, speed 4. Might be possible to turn power down even more. In short, to cut or engrave reduce the power by 1/2!

8/9/2011 by asc

Russ has confirmed alignment is as good as it is going to get.

Mars/Martins problems are explained because of the power issues and that the granularity of engraving has been set high to aid with testing.

As Mark details below, power is all over the place. Cutting 3mm mdf, 100% at speed 5 fails, charring and only partially cut. Whereas dropping speed power to 70%, 40% and even 30% succeeds with better cuts and no charring. Any ideas people?

A fan has died and to prevent dust being blown on to the controller a plate has been installed over the fan.

Current Fan:

Suggested New fan: cpc.farnell.com/jsp/displayProduct.jsp?sku=MF6760094&CMP=aballbrochure

7/9/2011 note by mars

I tried a comparative cut of something I've done in the past. There is no longer any noticeable scaling error on the x or y axis, and the alignment now seems very stable (thanks mattv!). However there are other problems which I'm not sure how to fix.

4mm perspex, 130x60mm cut and engrave. The first attempt I oriented the design along the top side of the bed (looking at the cutter). It managed to cut very well, but the engraving had serious problems. Also the whole job took much longer (22 as opposed to 12mins) than it has done in the past. Not sure why that is. I then tried orienting the other way: some way (<15cm) from the top side the cut no longer goes through. I also adjusted the bed height to get the surface closer to the top by one increment, hoping to improve the engraving. Didn't help, though it might have affected the cut efficiency.

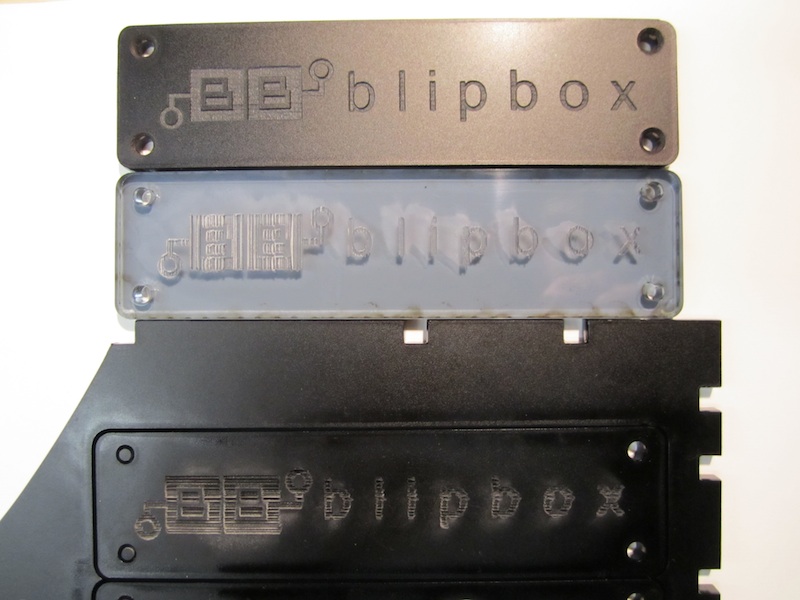

The picture shows from the top: a cut I did before the current problems; the first test with engraving striated vertically; and the last one which didn't cut all the way, and is strongly striated horizontally.

7/9/2011 by Mark

Asc spent a load of time trying various cuts and it seems that even at speed 4, power 100, it won't cut all the way through MDF. Concerned that the same laser tube issue had happened again.

The Z-axis endstop is broken, and someone had set the jog step up enormously, so take care with moving the base down.

30/8/2011 note by mattvenn

following up from asc...

1/- I have double checked the belts and tested for slippage, but didn't find anything. However, I believe that the cutting head has too much play. I can hear it chattering and I can wobble it around the (looking down on the cutter) z and y axis. The rollers aren't tight enough in my opinion, however this is no facility for adjustement. It's worth checking the rollers for wear, and then how about we build a replacement base for the cutting head with adjustable width?

2/- I have done cuts through 4mm ply across the bed to check for a longer cut and this started out looking OK. I then noticed relatively large wobbles cutting straight lines. This could also be explained by the play noted above.

By loosening the screw on the lower left roller (not the hex bolt) I was able to adjust the roller's position to nearly eliminate play in the cutting head. This has resulted in much better alignment.

Scaling: I also noticed that there is now a scaling factor of 1% on the x axis and 2% on the y (with x being the long axis).

I fixed this by setting pulse unit to 0.00635 for both X and Y.

Stuff that needs to be fixed:

- coolbot is not reliable, water temperature raised to 26 degrees while I was testing. Rebooting it makes it start cooling again. This was done twice today by me.

- etching is really patchy, seems more so with bi directional, something to investigate.

- alignment seems to skip by a few mm when it is cutting at high speeds (I've noticed at 200)

- won't cut 4mm ply whatever the z axis (focus) setting in bottom right corner of bed.

24/8/2011 note by asc

from mailing list:

Hello all, I have failed, I struggled last night to get it aligned. At times it would align nicely, but after a couple minutes it would get out of alignment. I am needing some help here. The problem I have is that for the next couple weeks I can't really make it in to the space (an hour or two here and there tops), after that I am then away until November. Things left needing to do: 1) Alignment of X axis (and Y but that isn't too bad). 2) After alignment a good long cut (30-45 minutes) needs to be made to make sure power isn't degrading over time. 3) Cleaner added to water (not urgent). 4) Russ also spotted that one of the fans by the controller needs replacing. Can someone with more knowledge on this help out? My time from now on cannot be relied upon, so we are needing a volunteer to get their hands dirty with this alignment fixing. So far: The X axis (from front to back of cutting bed) is a slightly off, enough to ruin cuts, I have tinkered and adjusted the tensioning on that belt to make it loose enough not to stress things, but not too tight to cause the stepper to slip. This tweaking was where I was getting temporary success in X axis alignment, but it just doesn't stay. Jasper and I inspected that belt to discern if there was some gunk or missing teeth but nothing was visible. Personally, I think the X axis belt is a bit tight - with judgement of tension being relative to the Y axis belts. The Y axis needs tweaking too but it isn't too bad. Russ created a nice template engraving (saved to desktop, as a .mol - so File->Open rather than File->Import), that works well on the A3 card in the stock pile. This was showing two problems, one being alignment and the other being accelleration and decelleration burn power issues (can be tweaked in software). This accelleration and decelleration issue is visible when you look at the end of the lines and see that it is cutting deeper, this is caused by the motors taking time to speed up and slow down and maintaining the same cutting power as when moving at full speed. Russ also made another template (unfortunately not saved) that nicely tests the Y axis accuracy. Essentially creating a box setting it to engrave, enabling bilateral cutting, and setting the step as 0.5mm. This engraves a box with many lines 0.5mm apart so any errors in X and Y axis are pronounced. It was doing "pairs" of cuts and at one instance doubled up - this indicates a minor Y axis alignment issue. The problem with adjusting the Y axis and checking the belts is that you need to dismantle the bed and mess around with the two Y axis belts. Last night I knew I did not have enough time to do it and reassemble it all, before knowing I am going to be essentially away until November. The Y axis belts were not inspected. Acceleration and Decelleration burning power needs tweaking too, but this can be done in software and addressed later. The previous problem of the cutter going off the bed and problem is explained as follows, though I would be cautious about adjusting tension willy nilly, it's a pain to get right. The tensioning of the X axis belt would have been either too tight or too loose. This causes slipping (the brrbrrbrrbrrbrr sound) and the controller to lose position of the laser cutter. So next time it cuts it tries to move the head off the bed. If this occurs turn off laser cutter, adjust X axis tensioning, then the arm and laser to be gently moved to the center of the bed. Power back on and the system will pull the arm back to the origin. You must power it off before gently moving the arm, this disengages the power to the steppers which then allows you to easily and gently move the arm.

22/8/2011 note by asc

from mailing list:

Hello Matt and everyone. Executive Summary: It's nearly fixed, hopefully by Wednesday - time and life permitting. > I've never bothered with cleaning the support mesh other than removing > it and vacuuming the bits out. It needs it every so often. Every cut leaves gunk on the mesh (once clean I was suprised it how much) and it appears overtime to effect the material being cut with the little flare marks - which i suspect is the gunk being vaporised and marking the material. The test cuts after the clean have been nicer. Though I wouldn't recommend doing it often as it is a dirty job and the mesh is a right pig to get flat again after taking out. > I checked ?laser from robonaut and there's a message about air assist > causing power drop, is this current? Nope, I'll update shortly. > I was thinking of coming down to London either later this week or > early next week, any time be good for a laser fixing session? > Matt I think it is pretty much set, I cannot Work done yesterday under Sol's careful eye: 1) Emptied the water. 2) Cleaned out all the pipes (the green ones had nice slime in them) - needed a stick with a rag to give it a good rigorous scrub. 3) Cleaned out as much as possible all the other water related stuff by rinsing in a mild detergent for ages. 4) Fixed kink in laser tube water cooler input. 5) Refilled system with new deionised water. 6) Conducted test jobs. Result: 1) Cuts are nice and sharp. 2) Cooling system is clean 3) Temperature looks all good. 4) Cuts are nice across the entire bed. Things still left to do: 1) Realign one of the axis, it is slipping. (Important) 2) Do a long test so make sure laser cutting is not degrading over time. (Important) 3) Put some type of restriction device to stop tubes having too much slack and being kinked. (Somewhat important). 3) Add something to the water to keep cootie free. (Not important) 4) Give the bed a chemical bath. (Not important) Observations: 1) There was a kink in the input water cooling pipe once the back cover was closed, this essentially meant not enough nice cool water was not getting to the laser tube. This would have meant the tube would have heated up and degraded its life. This looks to have been caused by curious hands. The cooling system works, but if can't measure the temperature inside the laser tube, (the kink was just before entering the tube). 2) One of the axis is slipping a bit, this will be fixed tonight, tomorrow or Wednesday night. Time permitting. 3) Alignment of optics looks all good at the moment (thanks to Sol). 4) Something needs adding to the water to stop growths - does anyone have any recommendations? 5) More people need a good training in servicing, too much burden is being put on too few people to maintain and fix the cutter. We need to acknowledge that servicing and maintenance takes significant time and it is unreasonable to assume these responsibilities will be with someone else... it's a community, step up and help! Summary: Most of the things I and Sol have looked at and addressed these last few visits can be summarised: Negligence - resolved by a more training. Essentially people not understanding what the symptoms mean and their severity. Curiosity - There needs to be a boundary here. Dirty fingers, water contamination, and opening the back up and introducing a kink that broke the cooling system... Maintenance - people need to give it a clean or vacuum every so often, gunk forms on the mesh and debris. We aren't talking about a massive scrub down, a simple vacuum will help. To the person who regularly misunderstands my emails and irc comments, please refrain from snarky comments this time. If my english leads to any misunderstanding or confusion please email me off list. Or well volunteer yourself. -asc

12/8/2011 note by mattvenn

from the IRC channel:

- the power also has been degrading significantly quicker than expected.

- the whole system needs a clean,

- the air extraction cover whatsit needs looking at to determine why the laser head hits it,

- alignment so bad, cable to laser pointer was getting zapped

- and when cutting the arm goes completely off the table sometimes

9/8/2011 Note by Robert

Attempted diagnosis print across the whole bed area to confirm that the air assist nozzle is not being hit at any point.

"Run box" caused the print head to leave the print area and make a grinding noise, test aborted.

3/8/2011 Note by Russss

There were reports that the beam was hitting the air assist nozzle. This results in reduced/no laser power and the X stage getting hot (which is bad). I painted the inside of the nozzle with black paint (with the assumption that it'll burn off if the beam hits it), but couldn't manage to make it happen. I didn't try everywhere round the bed though.

Someone needs to see if it's working fine at all corners of the bed, and the X stage probably also needs tightening up a bit.

7/7/2011 Note by Solexious

Took apart the lens gantry to give it a clean: http://www.flickr.com/photos/solexious/5916437652/in/photostream

I also cleaned the bed, gave it a hoover and completed the "every 25 hours" tasks. Sadly this didn't fix the bi direction engrave errors, more investigation needs to be done.

26/6/2011 Note by Solexious

Lasercutter is back up and happy, no interlock in place for flow.

Coolbot is being logged to csv files in /home/solexious/coolbot on babbage, and the irc commands ?lasertemp and ?lasertube have been added.

There still seems to be a issue with bi-directional engraving causing ghosting, seems something on the x axis (the one holding the lens to the moving rail) is loose.

20/6/2011 Note on behalf of Russss

21:36 <@solexious> So, none of the lasercutter users so far today have used the log, win... oh no,

the opposite of win

21:37 <@russss> solexious: and I did the intro for them too!

21:37 <@russss> solexious: I admit that I didn't use the log, but then I did tell you directly :P

21:38 <@russss> and 90% of the time I spent was with the laser not working...

21:40 <@solexious> incoming meddling over vnc to remind them!

21:40 <@russss> if you're meddling, could you tell them to make sure there's not too much water in

the back of the machine?

21:40 <@russss> if it is indeed in use

21:40 <@solexious> okie dokie

21:41 <@russss> solexious: oh, also have you noticed that one of the cooling fans is broken, and

the other one sounds like it's on the way out?

21:41 <@solexious> russss: no i had not, swear they were working the other day!

21:41 <@russss> solexious: ok, interesting.

21:41 <@russss> lots of dust in the electronics bay too

21:42 <@russss> but I guess that's to be expected. Could do with a good hoover out

21:42 <@solexious> gave it a quick can o air, but a hoover would be useful

21:43 <@russss> I suspect with one fan down, dust from inside the cutting chamber could potentially

re-enter the electronics bay

21:43 <@solexious> bah, vnc fail, oni, could I ask you to poke them about the log plox

21:43 <@russss> and that would be bad.

17/6/2011 Note by Solexious

Beam aligned, but the cartage holding the lens is loose, this could be causing the ghosting when engraving with bi-direction on.

Cool bot is mostly rebuilt and will be reinstalled on Sunday the 19th

16/6/2011 Note by Solexious

Confirmed tube death, new tube working as expected.

Still to do: Align, and rebuild cooling and also give the bed a good cleaning.

14/6/2011 Note by Ciarán on behalf of Solexious

The following is from this mailing list thread.

- After working on it today, and changing the optics, it is obvious now that it has suffered a tube :death. The lasercutter is currently in pieces and is not safe to use. The cutter will be out of :action till some time on Thursday when we have the missing bits to install the new tube. (whom ever :thought it was funny to pressurise the sealant gun till it ruptured owes us a new tube)

- On the plus side we are taking this down time to add rfid to the laser cutter thanks to Mark (no :more loosing the keys \o/) and I am also switching out coolbot from an arduino to a nanode, this :will allow us to graph cooling temperature and also log laser usage hours (as sadly alot of users :don't bother any more, shame on them!)

3/6/2011 Note by Solexious

Cleaned out the cooling pipes with a raise in through put on the main pump.

The cutter needs some tlc and cleaning, but nothing show stopping.

4/2/2011 Note by Mark

Laser makes a nasty noise when moving diagonally. I assume it needs some tightening around one of the wheels.

6/3/2011 Note by Ciarán

- Solexious performed some maintence on laser, details

5/3/2011 Note by Mark

The laser cutter PC power supply is a bit dodgy. Straight after turning the machine off, it refused to turn back on. No response to the keyboard or power switch.

Replugging it multiple times had no effect, although after leaving it for a while (30 seconds) it booted automatically when plugged back in.

23/2/2011 Note by Tom Newsom

- Lazor PC has trouble booting. If it gets stuck on the blue windows screen, hard reboot, hold F8 and choose last good configuration

- Please don't do this. Last good configuration can screw up the registry in confusing ways. Ms7821 09:19, 23 February 2011 (UTC)

- righto. Bloody windows!

10/2/2011 Note by Solexious

- The cutter has now been fully aligned

9/2/2011 Note by Solexious

Problems found:

- Flow through the system was 1/4 the speed it should have been.

- The flow interlock had gummed up with gloop and had failed not safe. The bung inside the mech had jammed causing the tube not to be shut off.

- This would have caused limited cooling of the cutter, not detectable by coolbot.

Solutions undertaken:

- All pipes and interlocks were cleaned out and flushed. A dead bee was removed.

- Further flow tests brought the flow back to 95% of the maximum flow possible for the pump, this is well within good bounds

- The old tube was replaced, new tube hooked up and tested / aligned.

- New deionised water was swapped out and flushed through the system.

Further steps:

- Obtain inline filter and a external filter for cleaning the tank.

- Investigate adding a flow meter so the flow can be graphed and alert us if the interlock fails again.

- Add outflow heat temperature sensors (hotbot)

- Investigate methods of keeping the deionised water free from gloop

Outcome:

- The laser is now working again, and at the power level we had when we first got the cutter.

- A short alignment session happened, but a longer one is needed to have the alignment spot on over the whole bed.

8/2/2011

- Actual case of bug being found in lasercutter cooling system

3/2/2011 Long discussion with lots of information on IRC, edited by Mark

Summary:

- We're getting a new tube by Tuesday

- Parts of it are dirty

- Coolbot is being dealt with by Solexious, please bear with us

- After replacing the tube, we may insist on Coolbot being used at all times

- We need to look into the cleaning process seriously

18:54:21 <@solexious> the cutter is only up for doing tiny jobs for training 19:23:16 <@solexious> right, the lasercutter is out of order, please don't use it or the cooling system till we have the new tube 20:44:57 <@solexious> lovelace_: the WHOLE system is out of order and not to be used, when the system is working the cooler is working too 21:08:11 < lovelace_> basically, the whole machine is "filthy". every mirror, the inside, and the outside of the laser tube is covered in crap. we are documenting it. 21:08:35 <@solexious> lovelace_: 2 of the mirrors are NEW 21:08:44 < lovelace_> doens't make them clean 21:08:51 <@russss> lovelace_: I assume that is because people have been running the laser while it's had an "out of order" sign on it. 21:08:56 <@russss> and nobody's known to clean it. 21:09:02 < lovelace_> yup 22:11:11 <@solexious> could you tell him hpc can get us 2 tubes on monday/tuesday and its £195 +vat +del 22:35:23 < kal> Sol: There is a hole on the water cooler that looks like it can be adjusted for regulate the amount of cooling. but it as a screw instead of nob 22:35:27 < kal> knob* 22:35:46 < kal> does that do anything/ have you tried to adjust it? 22:36:21 < kal> for = to* 222:38:07 < artag> kal, the cooler itself is a chiller for drinking water. It tries to get it's coil temp down to a few deg C. This is much too cold for the laser tube. Coolbot pumps water from the tank through the chiller when the tank is warm. The screw adjusts how hard the chiller tries to get down to low temps. 22:40:04 < artag> since the tank is always fairly warm when coolbot needs to cool it, the chiller's thermostat will be on regardless of that screw setting 22:45:40 <@solexious> kal: i ask for leaving coolbot as it is my project, rather than a general hackspace item 00:20:28 < BytePilot> (sigh) well, cleaning its internals was a good plan anyway, 00:20:46 < BytePilot> solexious: I had a good peek at tht tube, it's _full_ of grot 00:20:58 <@solexious> BytePilot: yup 00:21:31 < BytePilot> and that MDF is icky tarry stuff. Porr machine had ick in places where nobody should have ick. 00:21:47 <@solexious> BytePilot: the lens and mirrors were cleaned a few days ago, with 2 of the mirrors being new 00:22:16 < BytePilot> solexious: (wince) Ouch. 00:22:31 <@solexious> and it hasnt been used much at all 00:23:09 < BytePilot> solexious: the mirror on the back of the flying Y axis was _filthy_ utterly coated in gak, and I gleaned literal Lumps out of the wee hole in the mount for the vertical mirror 00:23:57 < BytePilot> Might be worth saying "acrylinc/laser ply only" until we know what the trouble is. 00:23:59 <@solexious> ah yes, that one still needed doing, one of the reasons it was out of order, sadly the sign had apparently been removed 00:24:17 < BytePilot> I didn't open the power supply chamber, but I'm guessing that could do with a frisk over too 00:24:42 < BytePilot> (HeadDesk) 00:25:35 < BytePilot> also, we couldn't get the coolbot interface to work (ie suppy power to the subsidiary pump), is there something we needed to know ? 00:26:04 <@solexious> BytePilot: no, its all just out of order at the moment 00:26:35 < BytePilot> I'm also going to take screenshots of all the settings for the machine I have here, and compare them to those you have there. Just in case someone has fiddled with a number they shouldn't have. 00:27:14 < BytePilot> There'll be some differences in bed size/shape but the power output settings should be similar. 00:27:15 <@solexious> BytePilot: sounds good, ive also got a full copy of the software/settings backed up 00:27:36 <@solexious> (from when all was working well) 00:27:39 < BytePilot> Solexious: good plan. that 35%=100% thing gives me the fear. Something is _very_ odd there. 00:28:06 <@solexious> BytePilot: have you had a tube fail on you? 00:28:44 < BytePilot> Solexious: Nope, not even any significant power drift. and my cooling water came out of the tap (via a water filter) 00:28:49 <@solexious> and 35%==75% 00:29:35 <@solexious> ^ pedant 00:29:44 < BytePilot> solexious: (grin) I'm going to stay awy from actually using the poor thing until it's behaving comprehensably again. 00:30:37 <@solexious> cool, thanks for saving me from giving it another clean 00:30:48 < BytePilot> solexious: we got the subsidiary pump working again (percussive maintainance) and it's now ganged into the switched socket with the main pump, since they only draw 500ma between them 00:31:59 < BytePilot> Solexious: S'cool. I think people are taking advantage a little, making you clean the machine for them. I know that some parts need delicate handling, but they should at least vaccum out their dust 00:32:01 <@solexious> oh christ, i hope the cutter is off till i get there to un do that 00:32:15 < BytePilot> solexious: why ? 00:32:27 < BytePilot> solexious: it works, and works well. 00:32:31 <@solexious> it will chill the tube to 7 degrees 00:33:00 < BytePilot> solexious: seven degrees ? How ? 00:33:19 <@solexious> i was told that the coolbot had been left alone after numerous requests on irc 00:33:20 < BytePilot> solexious: the chiller isn't even close to that powerful. 00:33:51 <@solexious> BytePilot: it is, thats what happened before coolbot when the cooling system is manual 00:34:03 <@solexious> s/is/was/ 00:34:15 < BytePilot> Was the chiller left on 1005 of the time ? 00:34:19 < BytePilot> 1005 even ? 00:34:29 < BytePilot> (bugger, pokes shift key) 00:35:06 <@solexious> it was left on over night, came in to a box of 7 degrees water 00:35:49 < BytePilot> The pump that drives the water to the chiller will only come on when the pump that drives teh water to the laser is also on 00:35:50 <@solexious> its slow, but can chill quite well 00:36:14 <@solexious> BytePilot: if the lasercutter is left off 00:36:50 < BytePilot> (blink) you're not telling me someone left the entire rig on overnight ? 00:37:11 < BytePilot> Ok, that kind of criminal idiocy we didn't think even possible. 00:37:44 <@solexious> and as my requests for it to be turned off and left alone were ignored, im not expecting that to be followed now 00:38:44 <@solexious> BytePilot: sadly i've come to realise you have to treat people as idiots in the space (alto most people arnt, just miss guided) 00:40:16 < BytePilot> (thinx) Could sense the laser power and drive the chiller off that. 00:40:24 < BytePilot> No that's no use. 00:40:33 < BytePilot> still allows idiocy 00:40:55 <@solexious> BytePilot: when the system isn't out of order it works well, its just the human element that breaks it :) 00:41:12 < BytePilot> Solexious: Aye, and we're going to have to sort that out. 00:41:40 < BytePilot> solexious: I honestly think that one of the best things we could do is move the laser out of the "dirty" area and into someplace less full of dust. 00:42:31 < BytePilot> Solexious: The tube chamber at the back of the cutter was full of fine sawdust, I had to clean the outside of the tube before I could be sure that the inside really was gunky (it really is) 00:43:32 <@solexious> its pretty much a sealed box, its more likely thats from cutting mdf than from the workshop 00:44:02 <@solexious> and the sealed cooling system didnt get shite into it, just a shame it got busted in the move. 00:44:19 < BytePilot> solexious: In which case, definitly less MDF, t 00:44:31 <@creature> I've been cutting some mountboard recently. So if the dust was more like burnt paper than MDF, I could have been the source. Sorry, if so. 00:44:46 < BytePilot> solexious: cooling system is a lot more sealed now. I'd go so far as to say it's very sealed 00:45:12 <@solexious> BytePilot: I think just a forced log book so we can see at a glance how much use it getting and do full cleans accordingly 00:45:23 < BytePilot> Creature: Unless your mountboard was light brown and you were cutting a lot of it I'd go with MDF 00:45:45 < BytePilot> solexious: tricky to enforce. 00:46:07 * solexious gets out his boom stick enforcer 00:46:10 < BytePilot> solexious: (does thinking in head) 00:46:33 < BytePilot> Also, I couldn't find any white lithum grease, or isopropanol in the space, 00:46:56 <@solexious> but once we have the relaser software we can log it electrically 00:47:10 <@solexious> was the iso ont next to the sink? 00:47:11 < BytePilot> vodka works for clearing gunk, but some parts of the machine need a "proper" clean 00:47:32 < BytePilot> solexious: not that I saw (shrug) possibly just me being blind 00:47:44 <@solexious> heh, it hides from me alot too 00:47:55 < BytePilot> solexious: so long as people aren't drinking it 00:48:00 <@solexious> take it you found the cleaning kit 00:48:20 < BytePilot> solexious: (grin) I didn't someone found it for me 00:48:48 < BytePilot> solexious: Oh, also, remind me to bring a Z-axis ruler 00:49:10 < BytePilot> solexious: excellent pre-cut suare that's just the right height to set the laser above your cutting surface. 00:49:14 < BytePilot> (square even) 00:49:15 <@solexious> how come? and is it different from a normal ruler? 00:49:23 <@solexious> ah 00:49:47 < BytePilot> No need for any level of cleverness, just stick the square underneath and if it just fits you got it right 00:50:10 < BytePilot> (cut for the wee metal plate on the Y axis, not for the laser head itself) 00:50:12 <@solexious> not sure i can picture that... 00:50:25 <@solexious> oooh 00:51:02 <@solexious> i just put a ruler on the bed and move the z till it touches the top of the z ruler 00:51:30 < BytePilot> (grin) I don't trust my Z ruler 00:51:43 < BytePilot> because I know for sure my bed isn't flat 00:52:20 <@solexious> heh, after doing 0 tests on acrylic that seems to be the only accurate bit of the cutter 00:52:20 < BytePilot> Nor is the one at the space either alas. I don't think it's sloped, but it is lumpy. damn "honeycomb" 00:52:50 < BytePilot> (sigh) they are rather thrown together aren't they... 00:53:11 <@solexious> i take it you saw the x and y rulers with 10" 11" 11" 12" 00:53:28 <@solexious> still makes me chuckle 00:56:11 < BytePilot> worried me rather, wasn't sure I'd seen it right. 00:56:37 < BytePilot> Right, I'm off to kip. 00:56:43 <@solexious> nn 00:56:52 < BytePilot> I'll have a look at my own machine and see if I can see anything that looks suspect 00:57:09 < BytePilot> because grotty as the tube is, I'm not sure that's going to be our magic bullet. 00:57:24 < BytePilot> also, I think we might be able to flush the grot out. 00:57:43 < BytePilot> and we definitely need fresh water in the colling system, if's got "bits" in it. 01:02:46 <@solexious> BytePilot: by all means try, but I have given it a large flush

2/2/2011 Note by Naxxfish

- The lasercutter continues to be unhappy.

- The water gets warm quite quickly, and takes ages to cool down. (stays around 25C after doing a couple of jobs)

- Phish and Fish vacuumed the bed, reducing fires one bit of acrylic at a time!

- Seems to cut and etch OK with the "adjusted" settings.

20/1/2011 Note by Solexious

- The lasercutter is unhappy, here are its symptoms:

- Power varies during a job, regardless as to where on the bed it is cutting.

- If the cutter is paused for ~1min and started again the resulting power output will be noticeably higher.

- The exhaust water is flowing slowly, crap was removed from the flow, it now is back to full water power.

- I am awaiting for a call from hpc laser

19/1/2011 Note by MattVenn

Just to agree with Mark (below). I've spent about 4 hours over the last few days trying to get some settings that will cut 4mm laser ply. In the past, I have managed it in one cut! Now I can't do it with 8 passes!

19/1/2011 Note by Mark

- The laser cutter will not cut 4mm ply. It won't even scorch the bottom of the wood after 4 passes at speed 3 (and it's hard to tell whether it's cut or not without moving the target). I assume Z axis fiddling is required, but until a decent process is worked out, I've written a warning on the speed chart.

- Enormous difficulty on one pass at speed 5 with 3mm light (balsa) wood. Didn't cut all the way through, and we were again unable to tell whether everything was cut. A large part of the job hardly scratched the wood at all. Recutting this area caused bad singeing in places, so I don't think it's a power issue, but some places/curves still didn't recut.

If we can't work out how to fix the focus/mirrors, can I suggest contacting HPC Laser?

14/1/2011 Note By JasperWallace

- I dropped my hackspace keyring (one of the old ones from when we first had the cutter), and it shattered, it looks like stress was concentrated at the corners and it split from there - lesson learned: if you want cut things to last, specially if they are under any stress then round the corners!

11/1/2011

- Cooler was damaged in the move. SamLR reports 'we were moving the laser through to unit 23 the cooling unit fell over. We'd balanced coolbot on top of the water box so when it went over the whole thing got wet, beyond that I have no idea what's good to go and what isn't sorry'

- To the best of my understanding, the cooler is not operating and the coolbot cannot immediately be reassembled. Note that the laser tube can be damaged by both high and low temperatures; the laser operation can quickly take the coolant above the maximum and the uncontrolled cooler can take it below the minimum. Coolbot is required to operate the cooler safely, and even when operating correctly there is no automatic cutout so it can still be abused. However, much care should also be taken if the laser is operated without cooling. It can get outside the safe limits in half an hour or so. ---Artag 21:04, 14 January 2011 (UTC)

11/1/2011 Operator Matt Venn

- Helped get the laser setup in the new room

- Spent 30minutes fiddling with Z axis to get a decent and reliable cut on 4mm laser ply at a speed of 3.2.

- Laser spent 40 minutes cutting my pattern, but 80% of cuts didn't make it through the ply.

9/1/2011 Operator Alex P

- Used lasercutter to prototype a project in 210gsm cardboard. Worked fine for this, using a speed of 30, a power of 40, and a corner power of 20.

3/1/2011

- Went to test if it was Z-datum/alignemnt problem previously (see below), now it seems that the Layz0r shuttle PC does not want to power up.

Laser turns on, along with cooling equipment, and Monitor is in standby. Changed cable for the PC to check if the fuse was blown, didn't work.- Layzor PC seems to be turning on now, panic over.

- Tested laser z-axis problem. Scroll job = 1mm. Moving the platform down a few millimetres makes it cut 3mm MDF now.

31/12/2010 Operator Ciarán

- Tried to cut 4mm MDF using reccomended settings (speed 4, 100%). Laser cutter unable to cut through. Tried again with Speed=3, two passes and hit the "Z-Datum" button combo, but still laser unable to cut. Gave up.

- After speaking to Sol about the problem it may been caused by my own inabilities to set the z-datum correctly.

30/12/2010 Operator Elliot

- Tried to cut 4mm acrylic on my usual settings (speed 6, 100%). Cuts were uneven and often didn't break through. Retried with speed 4 and got a similar result. Could have been a Z-Axis issue as I'm still uncertain on how to align this - I just set the the top of my material to the '0' point on the rule. Previously I used to just press 'Z-Axis/Datum'.

15/12/2010 Operator Solexious

- Installed the improved cooling system.

- Flushed and replaced the deionised water.

- Cutter working well, but most cuts now require -1 to speed, may need to check alignment, or a tube issue.

14/12/2010 Operator Ciarán

- Started up laser, cut x3 small key rings from 4 mm MDF with Duncan. Not a problem worked perfectly.

- Later noticed when Glenn was cutting a lot of MDF that water heating up, and there was no return water coming from chiller.

- Topped up water in reservoir with distilled water to the line, so that Glenn could finish.

- Russ turned up and had a look. Seems that the pump supplying water to chiller worked fine when plugged into it's own power. Plugging the chiller into separate power didn't seem to do anything.

- Russ reckons there is a block.

- Needs further looking at, probably best only to use the laser cutter for small jobs until it's sorted.

6/12/2010 Operator Solexious

- Connected CoolBot to the cooling system, seems to be working as expected, documentation to follow.

- Cleaned mirrors and lens due to high usage of mdf creating dirt etc.

- Reports of slight reduction of cutting power in the bottom right of the bed, may be mirror alignment or bed levelling required.

4/12/2010 - 5/12/2010 Operator Elliot

- Cut some Arduino enclosures with some 3mm Palglas (acrylic). The material cuts really well and provides great results.

- Also tried to cut some 10mm Palglas. It did cut all the way through but I think that the thickness of the material impedes heat dissipation because there was a fair bit of melting. I may try a higher speed (was using 1) or multiple passes.

18/11/2010 Operator Elliot

- Removed and replaced the lid to clean out some perspex offcuts that were hindering the operation of the hinge.

- Cut some 3mm MDF with good results. The extractor and cooling system seem to be working well.

15/11/2010 Operator Solexious

- The cooling system was added inline after the exaust water flow from the laser. This was found to cause the safety controls to kick in and disable the laser.

- This was removed, and a separate pump added to the reservoir to keep the cooling of the water a separate system to the cutter pump.

- The system cools the water as much as possible while on, so needs to be controlled manually. A micro-controlled system to show the temperature/water levels and regulate cooling is currently being made.

14/11/2010 Operator Solexious

- Called into the space as the laser cutter software was crashing on compile. I found the machine settings were not those left by me the night before, and reset them. This fixed the issue. I have taken a back up of the now working setup, and also left a copy of this zip in the root of the C drive.

13/11/2010 Operator Solexious

- Added a new extractor fan to the cutter, it is more powerful than the current fan, and any more upgrades will also have to increase the air flow into the cutter.

- Due to Russ' fix for the x axis working so well I tested changing the acceleration and working speeds back to full. Meaning quicker job times. A complicated cut was preformed with 0% errors. Due to this the settings are now updated and uploaded to the machine.

23/10/2010 Operator Elliot

- I cut some Palglas acrylic to make a kind of box. Palglas seems to be a reasonable, cheaper alternative to Perspex.

18/10/2010 Operator Russ

- I etched my laptop (the complex piece in my previous log entry). X/Y alignment was perfect, no evidence of backlash.

- However, etching performance (actual delivered power) seems to be less in the top right-hand corner of the piece. This could either be due to beam alignment, or due to the bed/piece not being level.

16/10/2010 Operator Solexious

- After Russ fixed a problem with a drive shaft, I attempted to align the laser.

- The drive shaft slipped and came apart, I removed swarf from inside, and using hex bolts has given a tighter grip.

- These problems solved I aligned the beam and the laser power is now even across the entire bed

15/10/2010 Operator Russ

- I tried to engrave a particularly complex piece. The laser software naturally decided to plot this in a weird way, cutting parts of each line in turn instead of the whole path at once.

- This exposed a fairly severe backlash issue. Nothing joined up.

- This appeared to be an issue with the drive shaft linking both belts of the X axis. The part doing the actual linking was extremely poorly machined.

- I machined a new part on the lathe in 20mins, hastily installed it, and then had to leave for Hamburg leaving Billy to reassemble the laser cutter.

5/10/2010 Operator Russ

- Mirror was replaced with the new one from HPC.

30/09/2010 Operator Russ

- I was called to the space due to a report of the laser not working.

- It turned out that the #2 mirror had melted. Likely because I left some residue on it while calibrating the beam (it's hard to see that mirror).

- New mirror ordered from HPC (~£50)

23/09/2010 Operator Solexious

- Cutter working well, no skipping of steps after Russ and I fixed an issue with the far right drive shaft.

- The machine settings for speed of movement have been lowered to try to reduce drift during cutting.

19/09/2010 Operator Solexious

- After a failed attempt due to a slipping belt (probably the cause of the issues on the 18th), a money box was cut and assembled using the Box-o-Tron as a base for the dxf file.

- There is also a slight issue with focus of the laser, on 4mm acrylic settings of Speed 4 Power 100, at the side of the bed to the left it cuts perfectly, past 1/2 way to the right of the bed it fails to penetrate fully. A setting of Speed 5 Power 100 gives undesired blemishes from contact with the honey comb.

18/09/2010 Operator Meurig

- George cut some 2mm acrylic to make an enclosure for a robot.

- I created an XKCD plaque in copper using a two step (laser then chemical) process. These techniques will ultimatley be used to prototype PCBs. TBH, at this point the UV method is looking about as straightforward...

- We etched Aden's HTC G1 with pedobear, using Cut power 20, corner power 10 and speed 100.

- A Cthulu keyring was made on 2mm acrylic towards the end of the day. We did notice a few problems with this, namely at one point a hole came out non-circular, but also the etched layer didn't align correctly with the cut layer, out by about 2mm. No explanation for these at this point.

- I tried making a PCB, but should have used single sided copper.

16/09/2010 Operator Solexious

- Cut out the coin slot peices for the 4 in a row donations box

- Small bumps formed on the side of the acrylic closest to the bed where the honeycomb was touching, will try to correct with +1 to speed setting.

- Extraction is improved and unwanted smell is reduced with sheets of acrylic that are full bed size.

- No other problems detected.

15/09/2010 Operator Russ

- Cut some 1.5mm neoprene fairly successfully - needs high power and it's a bit smelly. (Settings in the book.)

- Circle issue is fixed. It was a problem with the tension on the frontmost X drive belt.

- Did some awesome etching onto black anodised aluminium - 450mm/sec, 90% power.

- We also built an acrylic box designed in qcad.

- Cut some hackspace keyrings, but noticed that the acrylic, when warm, warped upwards. Pause function worked as expected letting us tape down, but some ventilation sucking from below the bed would help a lot.

13/09/2010 Operator: samthetechie

Todo: Test CorelDraw X3 with 20mm circles on paper and compare to test using LaserCutter Software

12/09/2010 Operator: samthetechie

- Setup CorelDraw X3 with LaserCutter Add-on Toolbar.

- Cut Mic On Sign 3mm Perspex.

- Cut MusicMetric Sign 6mm MDF.